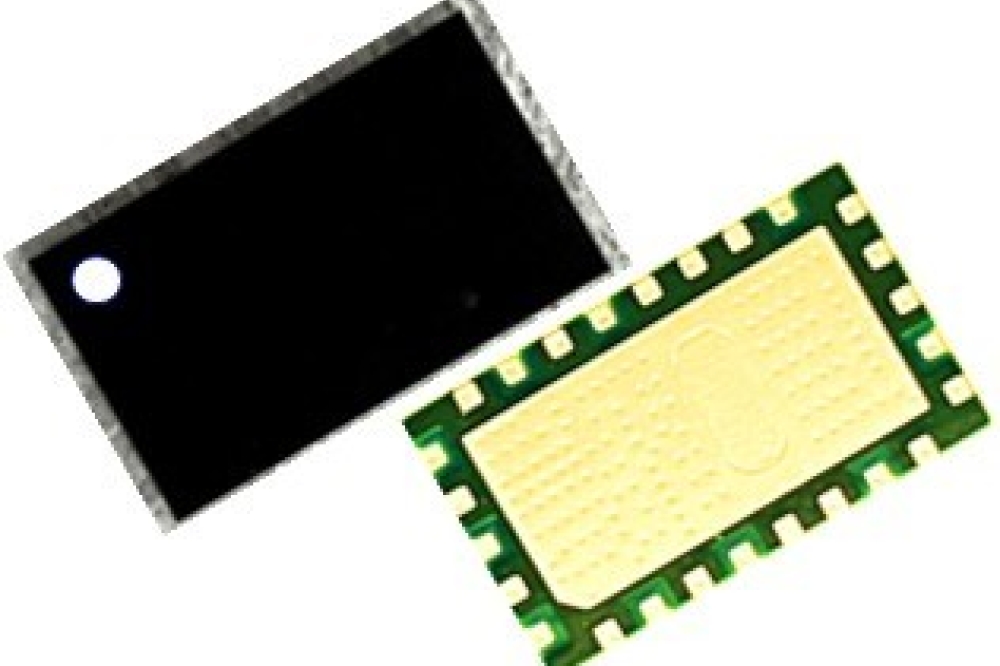

Macom gets CHIPS Act funding for GaN-on-SiC project

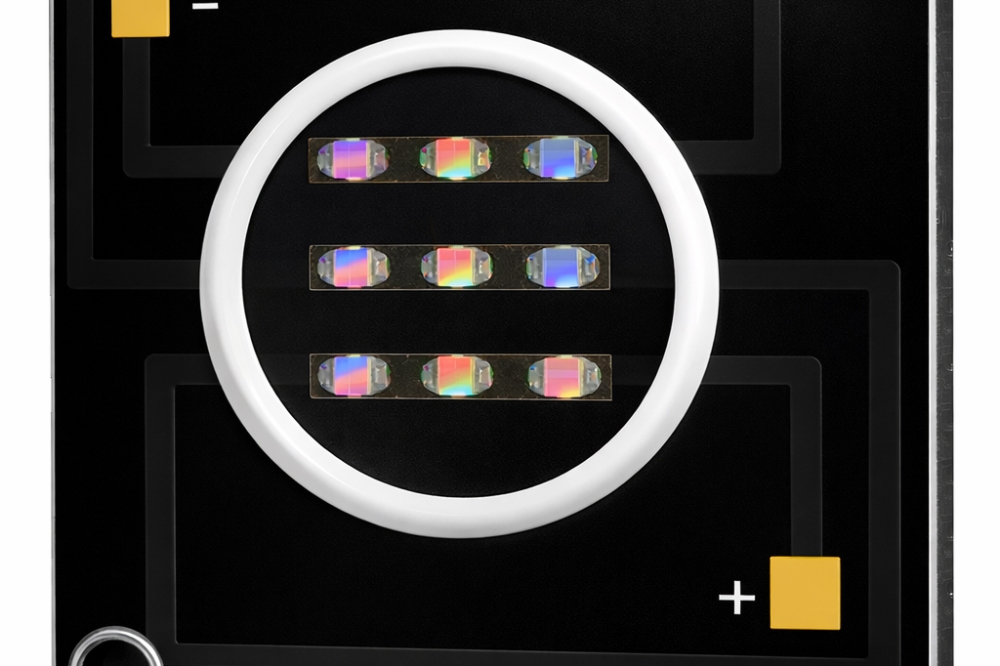

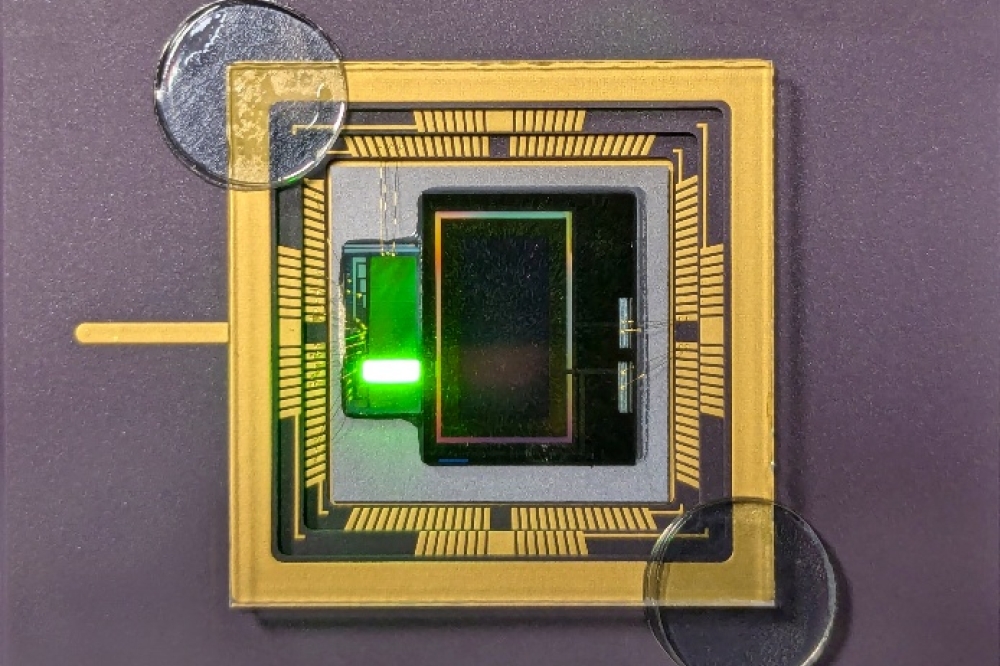

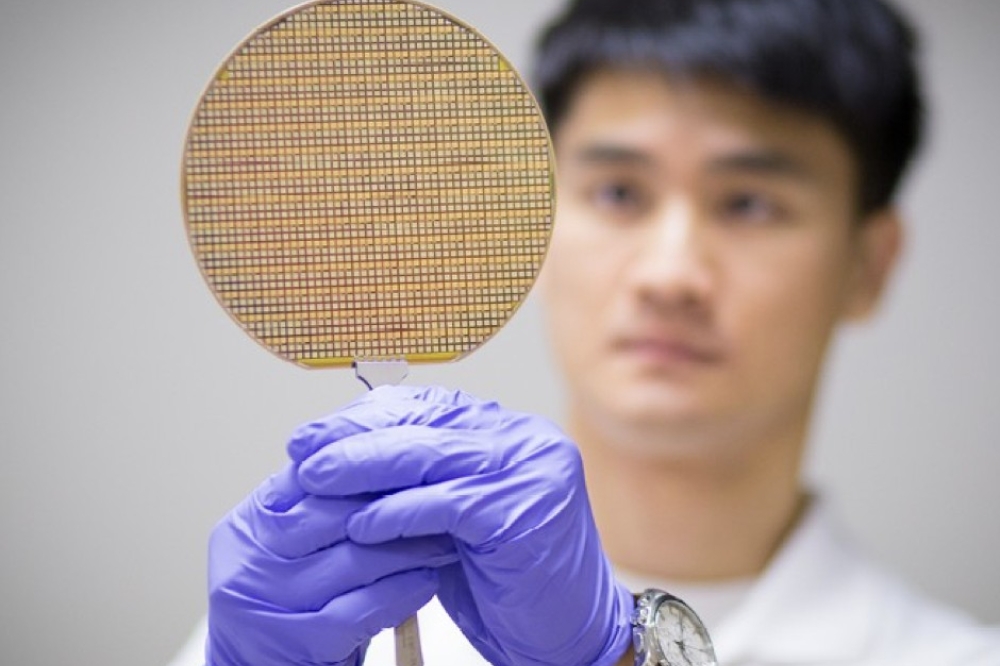

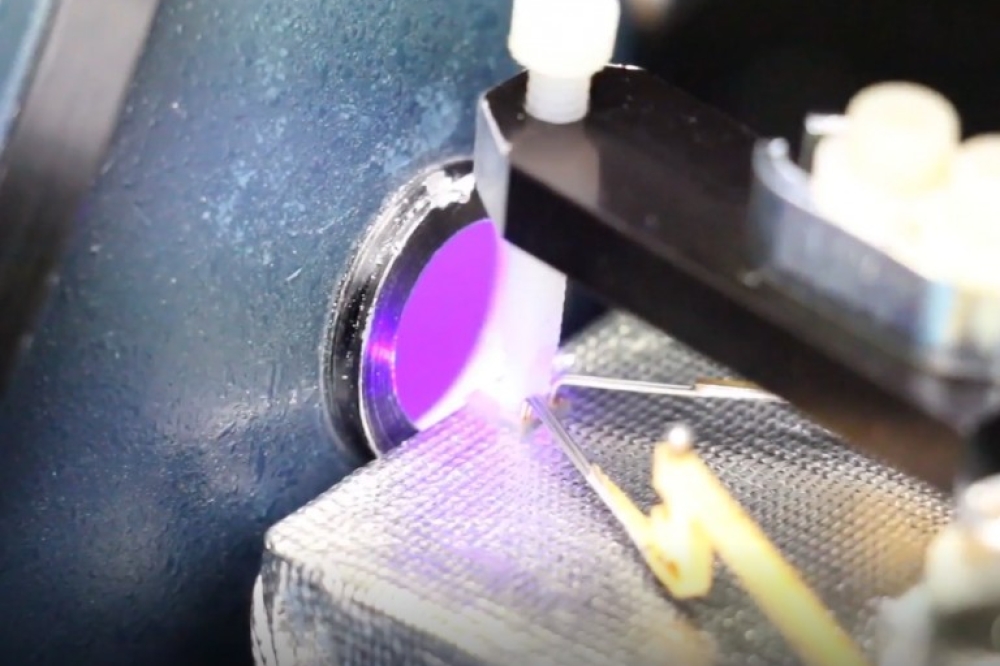

US semiconductor company Macom Technology has been selected to lead a development project to establish advanced GaN on SiC process technologies for RF and microwave applications.

Funded by the CHIPS and Science Act through the United States Department of Defense (DoD), the project will focus on developing semiconductor manufacturing processes for GaN-based materials and MMICs operating efficiently at high voltage and at mmWave frequencies.

Macom is a member of the Commercial Leap-Ahead for Wide Bandgap Semiconductors (CLAWS) Microelectronics Commons Hub and will work with North Carolina State University, Adroit Materials and the Naval Research Laboratory (NRL) on this project. The year 1 value of this award is $3.4 million.

This award expands upon a series of GaN technology development activities with the DoD, including a 2021 Cooperative Research and Development Agreement (CRADA) with the United State Air Force Research Laboratory (AFRL) where Macom successfully transferred AFRL’s 0.14 micron GaN-on-SiC MMIC process to its Massachusetts-based US Trusted Foundry.

This was followed in 2023 by a $4 million AFRL contract to develop GaN technologies for mmW applications and a Defense Advanced Research Projects Agency (DARPA) award valued at up to $10.1 million aimed at improved heat dissipation for high power applications.

Earlier this year, Macom was awarded a separate CHIPS-funded GaN technology development contract worth up to $11.4 million.

"Our strategy is to increase domestic production of state-of-the-art RF and microwave power technologies to support our military’s RADAR and sensing applications and to enable next generation telecommunications networks,” said Stephen G. Daly, Macom president and CEO. “We believe the technologies and products developed under these contracts will help keep the United States and Macom on the leading edge.”