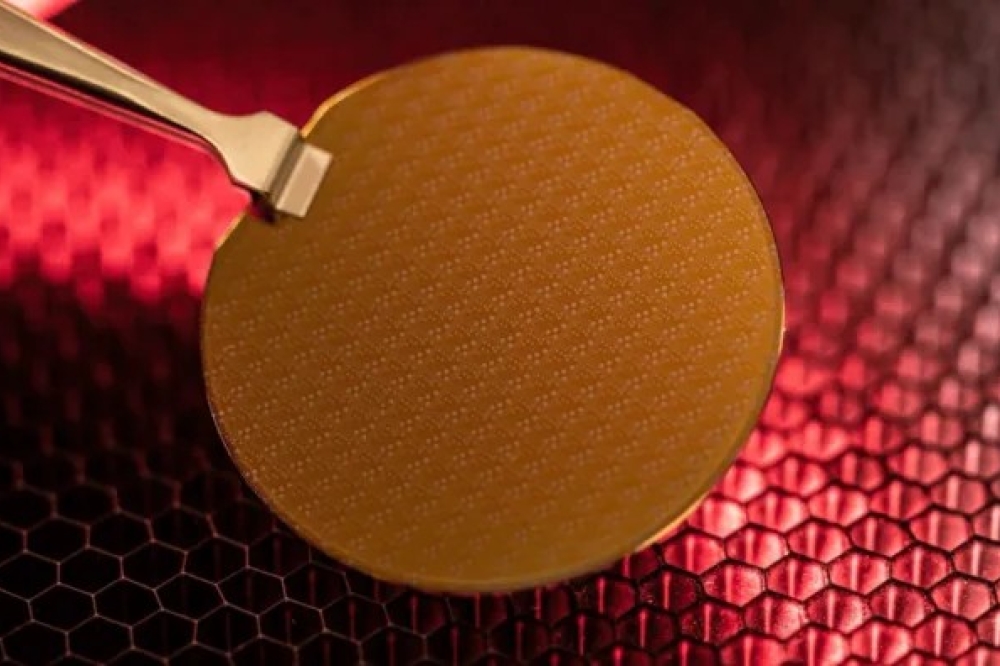

NexGen Wafer Systems introduces new platform

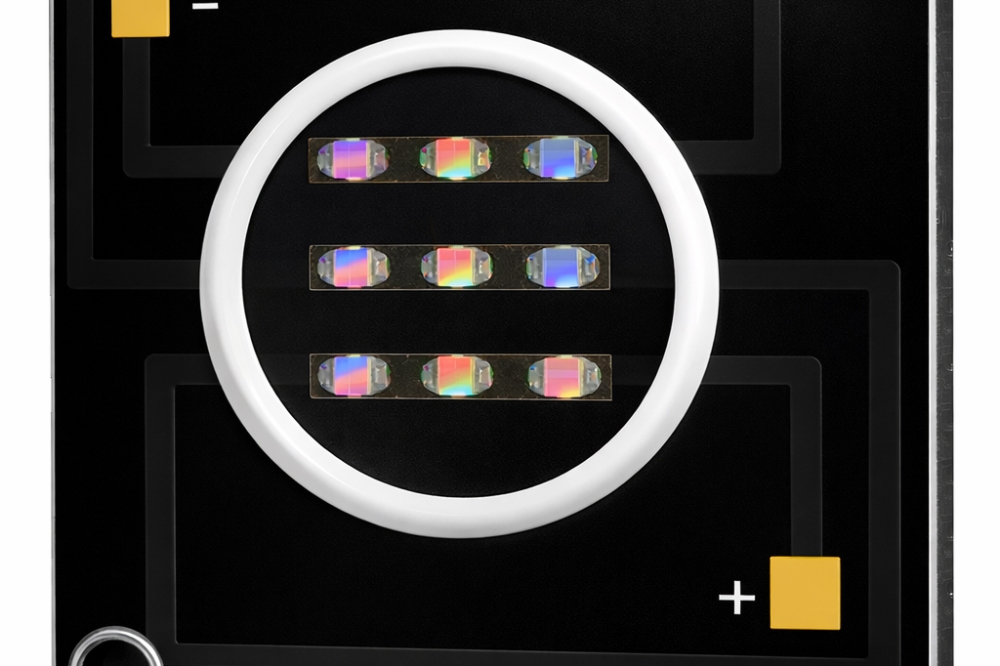

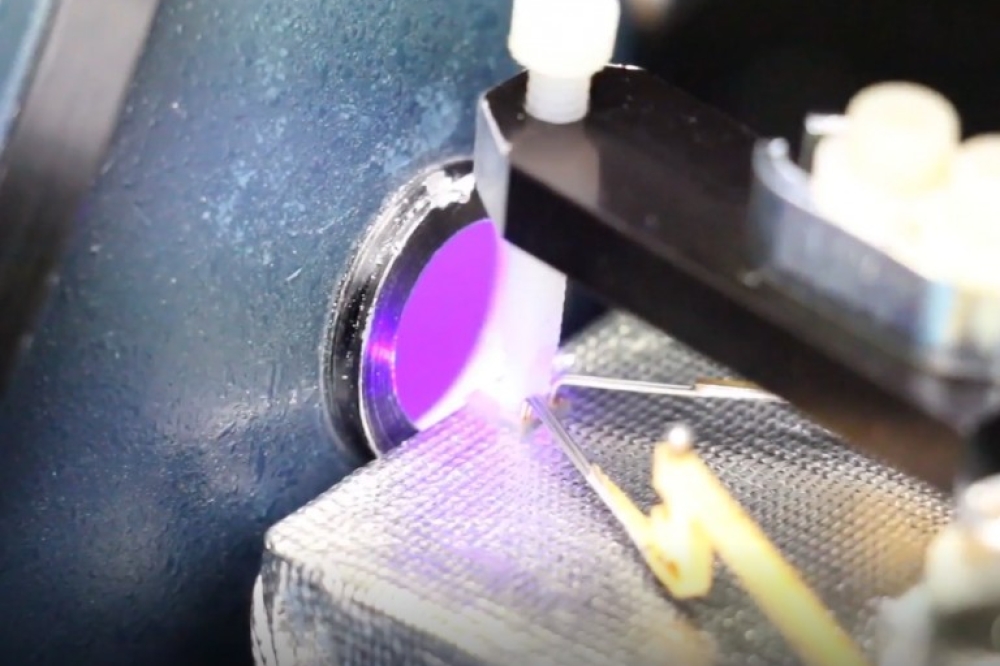

NexGen Wafer Systems has launched Sereno, its latest multi-chamber platform designed for Wet Etch and Clean applications. It supports 6inch, 8 inch, and 12 inch substrates made from Silicon, SiC, GaN, GaAs, Al2O3 and ZnO.

Sereno is said to combine high performance with flexibility, offering integrated metrology for precise substrate and layer thickness control, as well as surface roughness control. Its onboard chemical supply system supports multiple process chemicals with integrated mixing, blending, and comprehensive analytics, ensuring maximum adaptability across a wide range of applications.

It has a footprint of less than 12 m² and a throughput of up to 200 wafers per hour. It can support wafer thicknesses ranging from ultra-thin wafers below 100µm to bonded wafers exceeding 2mm in total thickness.

“With Sereno, we provide Wet Etch and Clean solutions that deliver high throughput in a compact footprint while maximising the flexibility and performance advantages of Single-Wafer Technology,” said Christian Kleindienst, chief marketing officer at NexGen Wafer Systems. “Our Sereno platform addresses our customers' demand for flexible, high-performance Single-Wafer solutions that reduce operational costs and present a highly attractive alternative to traditional batch tools.”

The Sereno platform is now available for orders, with first deliveries starting in Q1 2025.