Slashing solar cell costs

A dynamic variant of HVPE promises to provide a continuous growth

process that allows III-V solar cell production costs to tumble without

compromising performance.

BY RICHARD STEVENSON, EDITOR, CS MAGAZINE

If the only metric that really mattered for the solar cell were its performance, III-Vs would utterly dominate this market. But cost is paramount, accounting for the widespread deployment of silicon panels.

A primary cause of the high cost of III-V solar cells is the epitaxial process. Growth is relatively slow, using a batch approach that is inefficient, with time lost to loading and unloading wafers into a reactor that has to be heated and cooled.

Addressing all of these weaknesses is a team from the National Renewable Energy Laboratory (NREL) in Golden, CO, that is pioneering a novel approach to epitaxial growth that is referred to as dynamic HVPE.

One major asset of this particular technology is a growth rate that is typically an order of magnitude faster than that of the established epitaxial technologies for making solar cells, such as MOCVD. What’s more, this approach opens the door to moving away from batch processing.

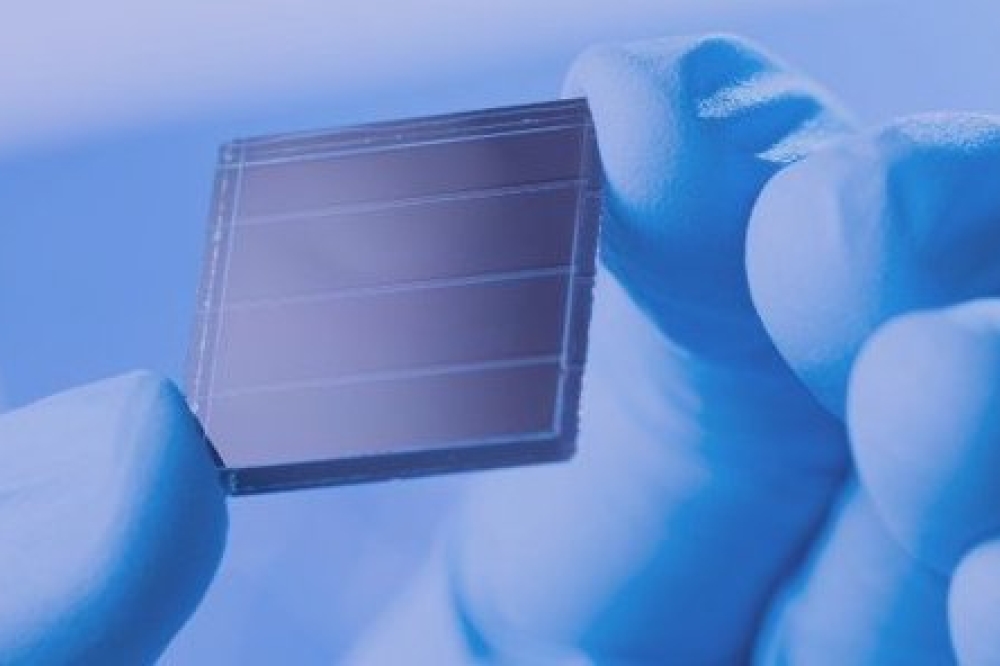

What's crucial is that all these advantages are realised while still allowing III-V cells to deliver a level of efficiency way beyond what’s possible with other material systems. The performance of solar cells grown by dynamic HVPE has been steadily increasing, and recently the team from NREL reported a single-junction cell with efficiency of 27 percent.

That’s still a little shy of the best ever performance of any single-junction cell, a record held by the now defunct Alta Devices, which announced a new benchmark of 29.1 percent efficiency in 2018. However, that record-breaking cell is thought to include optical structures to boost photon recycling and ultimately increase output voltage, according to Kevin Schulte from NREL. He has little doubt that without these valuable, performance-boosting optical technologies, which are not deployed on the NREL cells, the efficiency gap resulting from different growth technologies would be smaller.

The 27 percent efficient cells produced by the team from Colorado were made using a growth rate of 60 µm/hr, which is still well below the upper limit of what is possible. “We've grown solar cells up to 300 microns an hour without seeing significant degradation,” says Schulte.

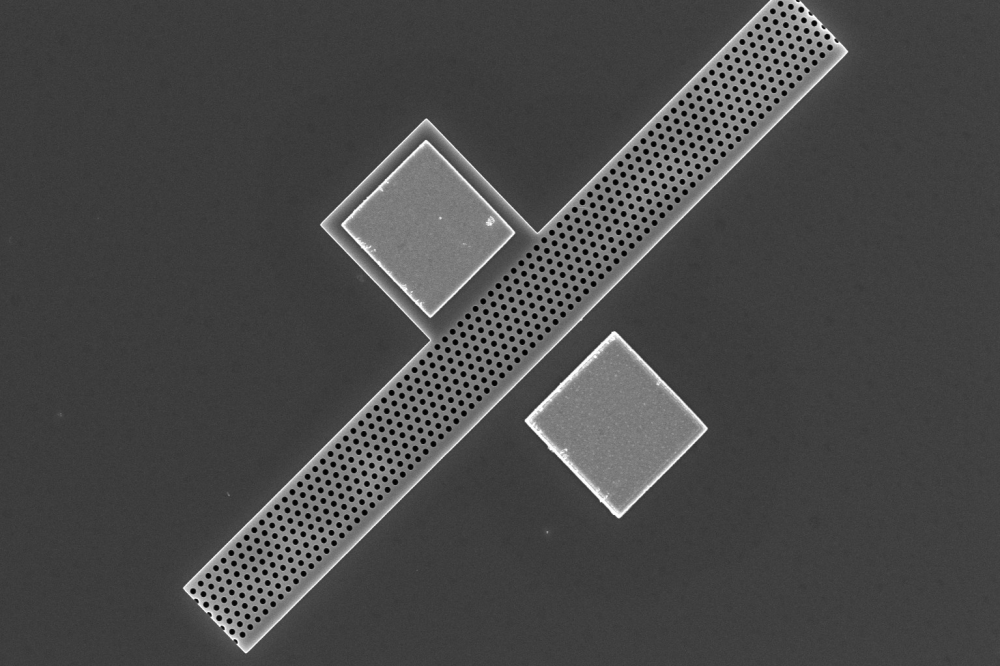

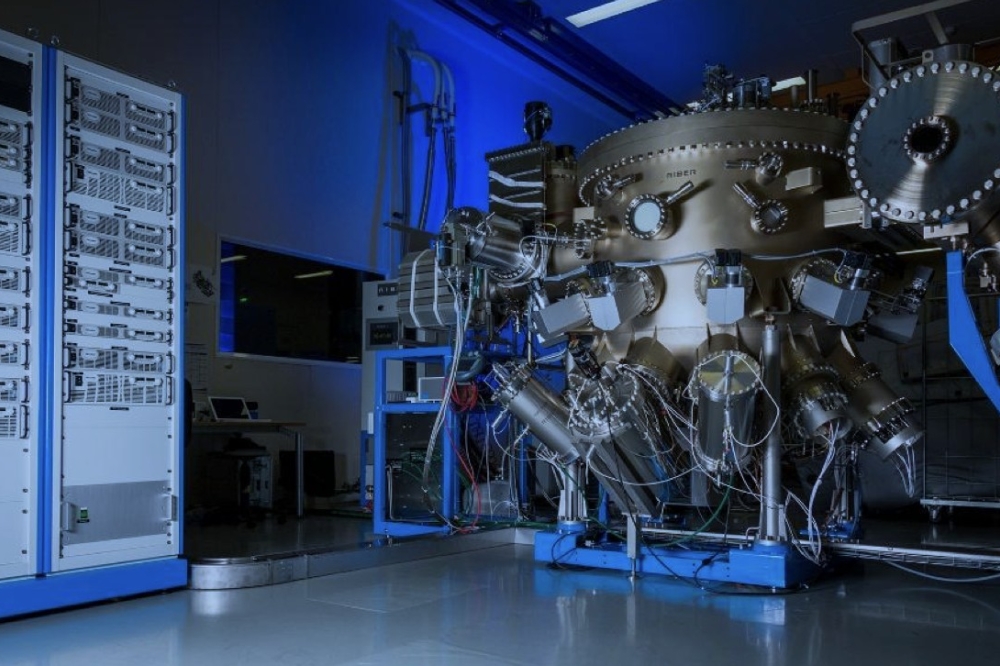

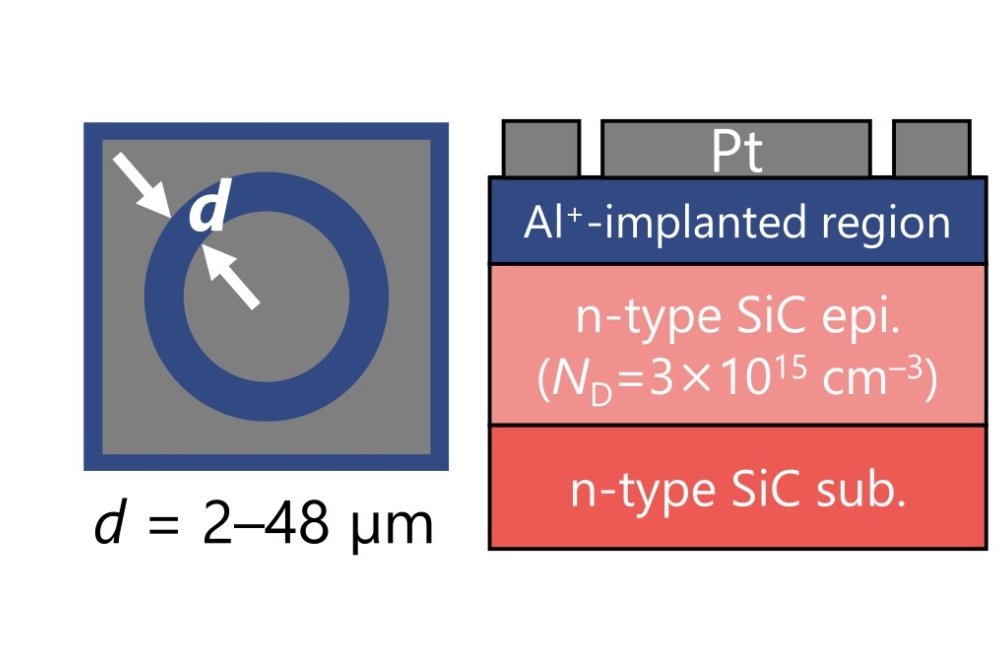

To produce their single-heterojunction cells, Schulte and co-workers shuffle wafers between the two chambers of their research reactor. While growth is taking place in one chamber, gas flows are switched in other chamber to prepare for deposition of the subsequent epilayer.

It is a modus operandi that provides a stepping stone towards the team’s grand vision of a linear reactor, containing multiple chambers that each provide the growth of a single layer. In this instance, as every layer requires a different thickness, the growth rate would vary from chamber to chamber.

In addition to the cost savings that come from higher growth rates and the more time-efficient approach associated with dynamic HVPE, there are financial benefits resulting from the use of different precursors. MOCVD demands pricey metal-organic compounds, while HVPE involves the use of precursors formed from reactions between metallic elements and anhydrous HCl. “The precursors are thought to be about an order of magnitude cheaper,” says Schulte.

Producers of III-V solar cells that adopt dynamic HVPE will probably begin by targeting the satellite market, which is able to sustain relatively high costs. Success there would enable an increase in production volumes, helping drive down manufacturing costs that would then allow device makers to pursue terrestrial opportunities, such as providing portable power or generating electricity in space-constrained environments.

Schulte is sceptical when it comes to whether a fall in the cost of III-V devices could ignite a resurgence in interest in concentrating photovoltaics. While lower-cost cells would increase the competitiveness of this technology, gains are marginal, as the price of the system is governed by other components, such as the optics and solar tracking systems.

“The problem is that silicon just got so cheap, so fast,” reasons Schulte, who points out that CPV has now missed out on many years of cost reduction that come from fierce competition in high-volume markets.

Modelling insights

To speed their development of high-efficiency, single-junction cells, Schulte and his colleagues turned to a freeware package called ASFORS-HET, previously available online and managed by the Helmholtz Centre, Berlin.

“It's a device physics simulator developed for silicon solar cells, but the fundamentals are the same for III-Vs,” says Schulte.

The package, which can produce current-voltage curves for different cells in a minute or so, enabled the team to hone its device design over several months. In particular, the researchers were able to fine tune the composition, thickness and doping of the emitter layer in their heterojunction structure.

While it would also have been possible to optimise the heterojunction cell with a purely experimental approach, this would have typically required ten or so calibration runs for each device. Due to this, many hundred runs would have been needed to reach the same conclusion, a considerable outlay in both time and money.

Schulte and his colleagues have also produced a two-junction cell with an efficiency of 28 percent. He says that even higher values should be possible, pointing out that a team in Japan has used HVPE to produce a III-V device with an efficiency of 28.3 percent. “Given enough time to optimise our tandem structure, I think we could get 30 percent or more.”

That’s not the primary focus for the team, however. Instead, efforts are directed at making larger-area devices, and trying to validate dynamic HVPE at what is approaching an industrial scale.

Helping succeed on this front is the installation of a pilot system in Colorado. This new tool arrived earlier this year, and the start-up phase is well underway.

Hopefully next year Schulte and his co-workers will be sharing device data from this tool. Success with that larger scale dynamic HVPE reactor would help to strengthen the case that this growth technology can produce efficient III-V cells in volume, and could ultimately help to drive the expansion of market opportunities for this device.