First line scanner with monolithic THz detectors

FBH terahertz line scanner enables cost-effective realisation of larger scan line lengths in industrial environments

Terahertz radiation is routinely used at airports for security checks because it penetrates clothing, organic tissue, and many other materials including plastics, polymers, and ceramics. In industry, it is suited for non-destructive material testing and for identifying hidden objects, for example to detect defects in the material.

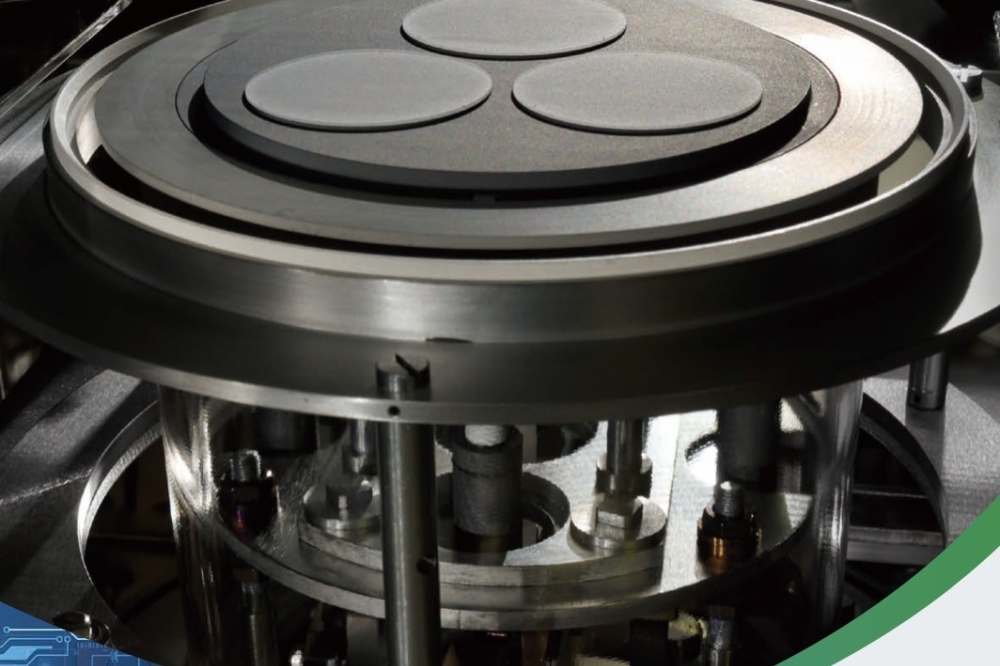

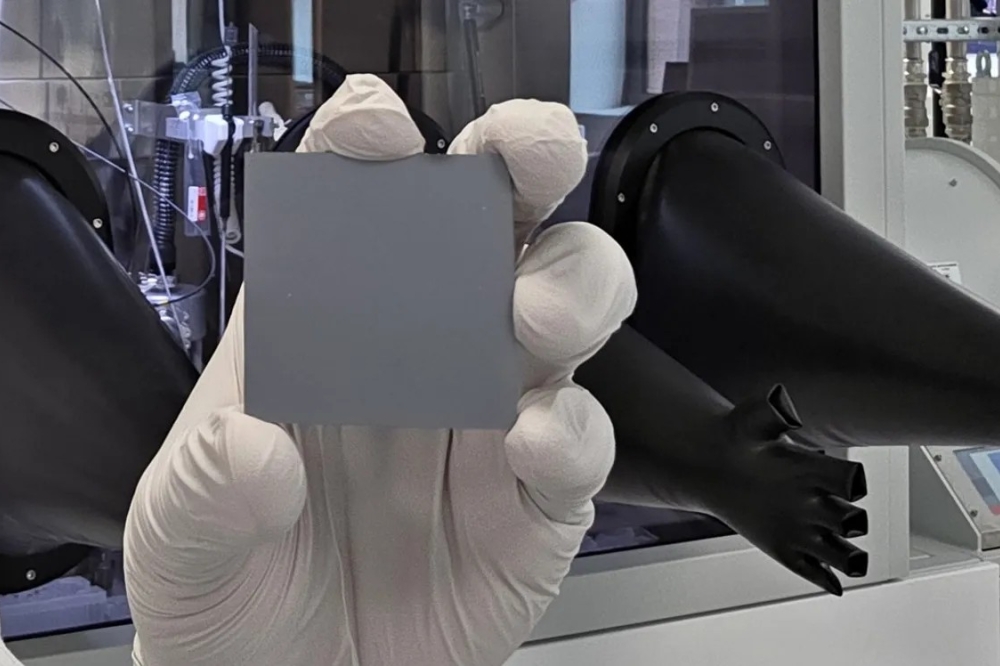

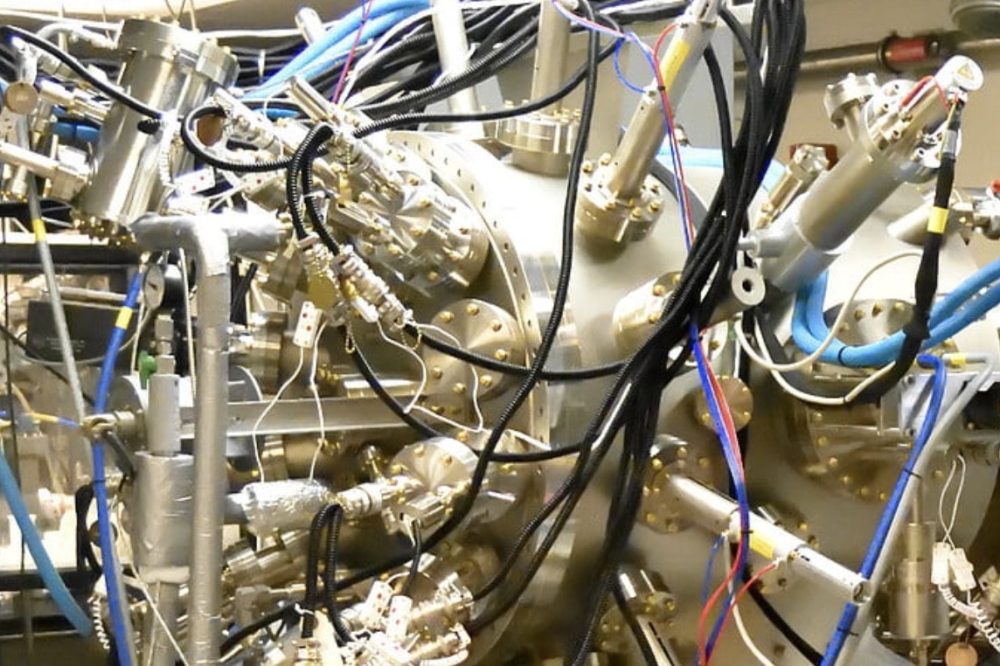

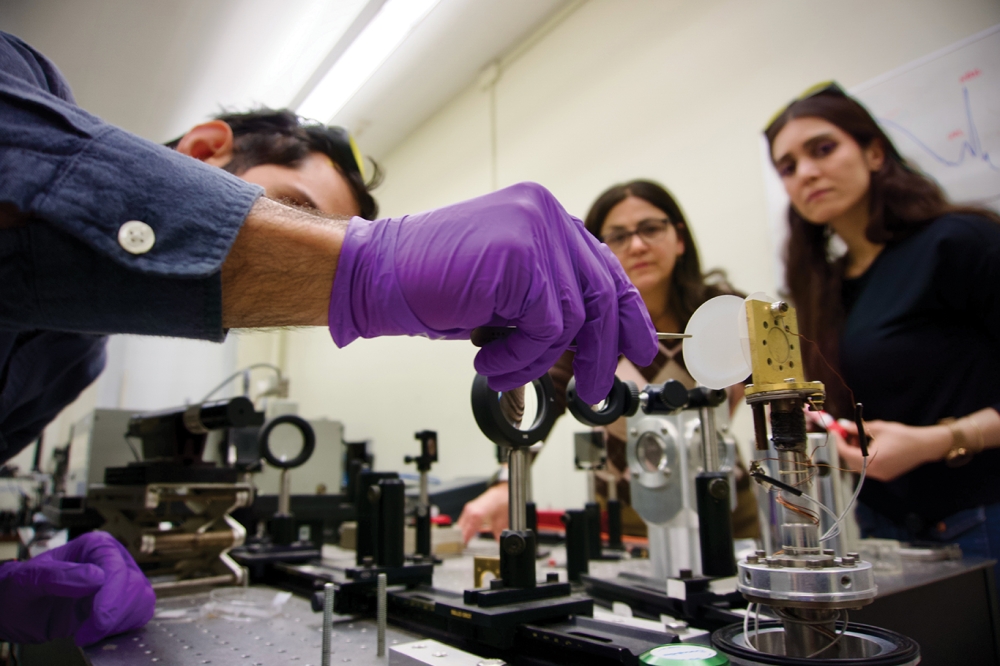

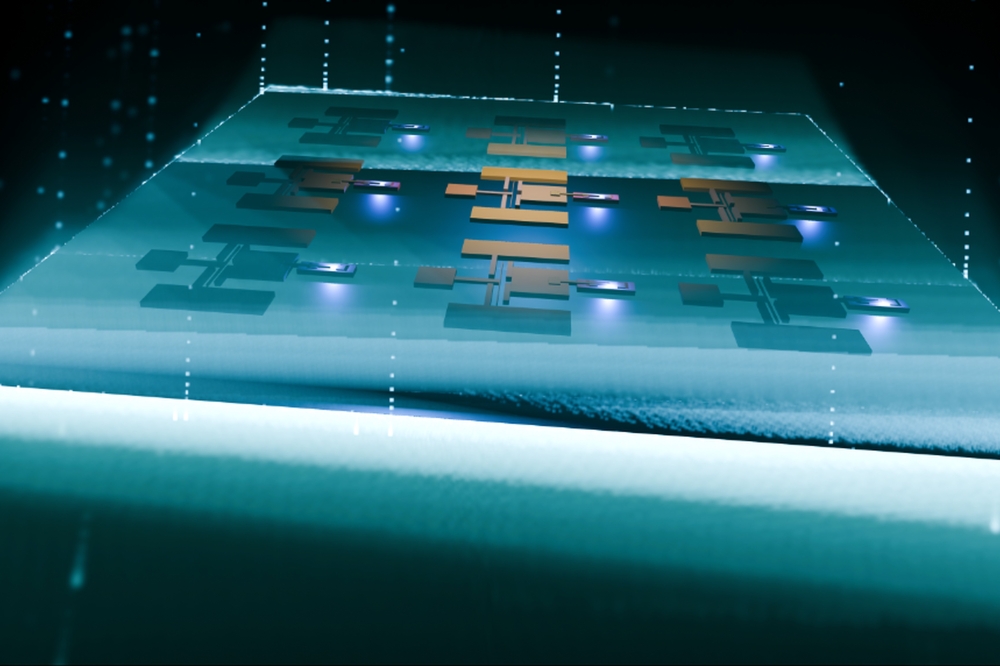

Now the Ferdinand-Braun-Institut (FBH) in Germany has developed a terahertz line scanner based entirely on monolithically integrated THz detectors. The scanner is is said to be unique in terms of scalability, throughput, and speed. Since the antenna structures are integrated on the chips, FBH says chip production can be scaled efficiently and cost-effectively to larger scan line lengths.

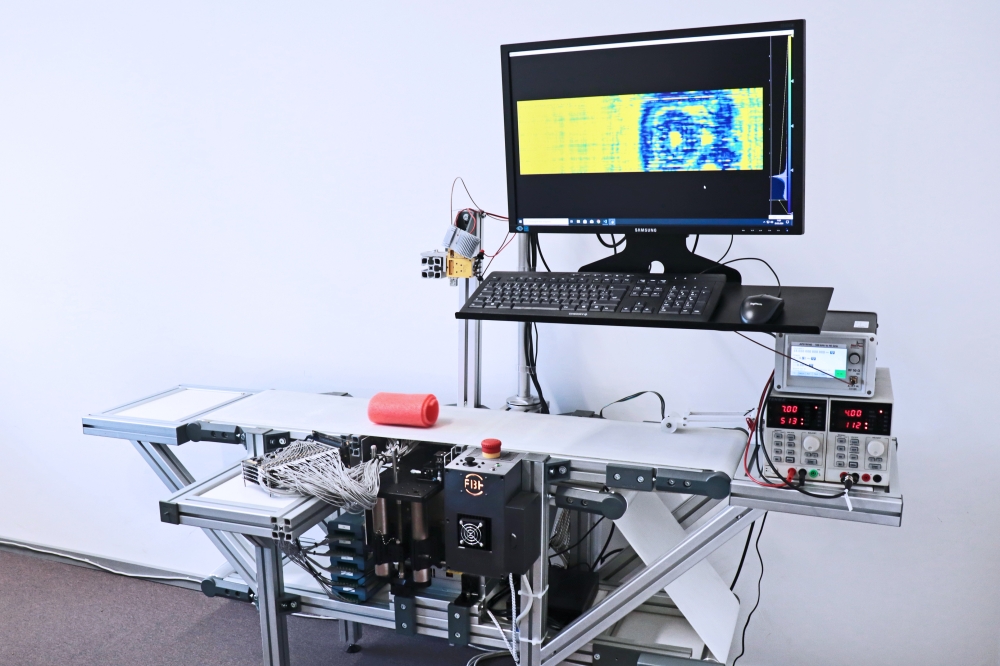

The demo scanner consists of a novel detector head that scans plastic parts on a conveyor belt – this scan is transmitted to a monitor along with a video image.

The detector head consists of a 6 cm long detector line, which is composed of 20 individual chips with four THz detectors on each chip. This amounts to 80 detectors, arranged at a distance of 640 µm. Depending on the terahertz source selected, these detectors can be used in the frequency range between 100 GHz and up to 1.5 THz. The speed of the 27-cm-wide conveyor belt of the technology demonstrator can be variably adjusted – up to 1.5 metres per second.

Each THz detector signal is amplified and digitised with a resolution of 16 bits. The readout speed of the line can be up to 15,000 images per second. Measurements of the THz detectors provide a bandwidth of at least 2 GHz.

Example measurements at 110 GHz with a sampling rate of 5,000 images per second demonstrate a recording speed of less than one second at a conveyor speed of 0.25 metres per second. This makes the THz line scanner an efficient and cost-effective solution for industrial applications, according to FBH.