AKM and SAL reveal eFuse for 800V car applications

Proof of concept shows that eFuse technology can improve safety, as well as reducing costs in systems such as on-board chargers

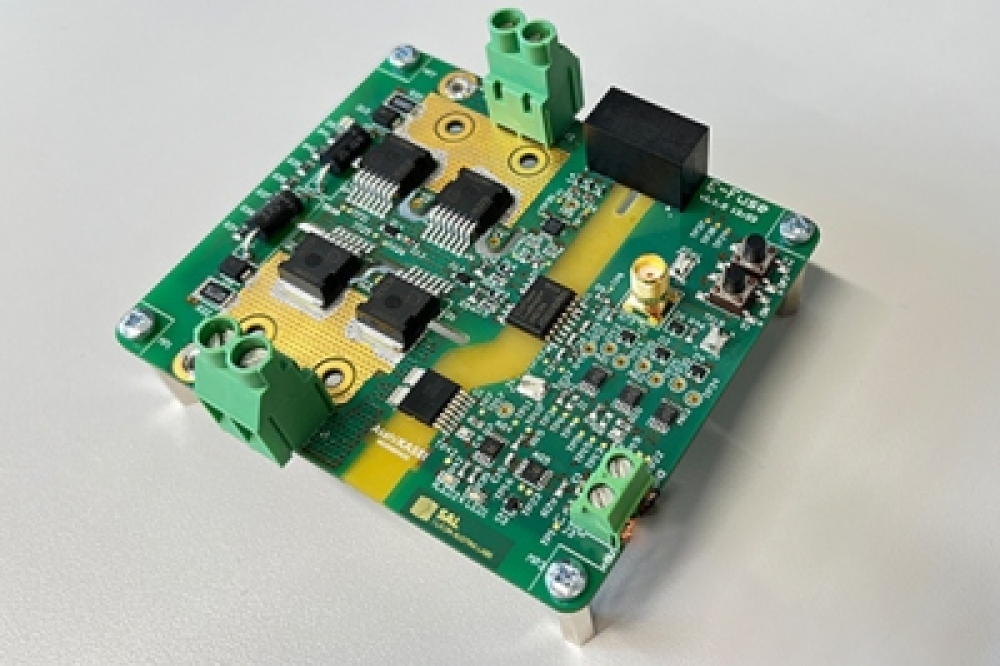

Asahi Kasei Microdevices (AKM) and Silicon Austria Labs (SAL), the European research centre for electronics and software based systems research, have completed a joint proof of concept of the eFuse technology in high-voltage applications using SiC-based power devices.

They say that the results show that eFuse technology can improve safety, as well as reducing material and maintenance costs of systems such as on-board chargers (OBC) in automobiles.

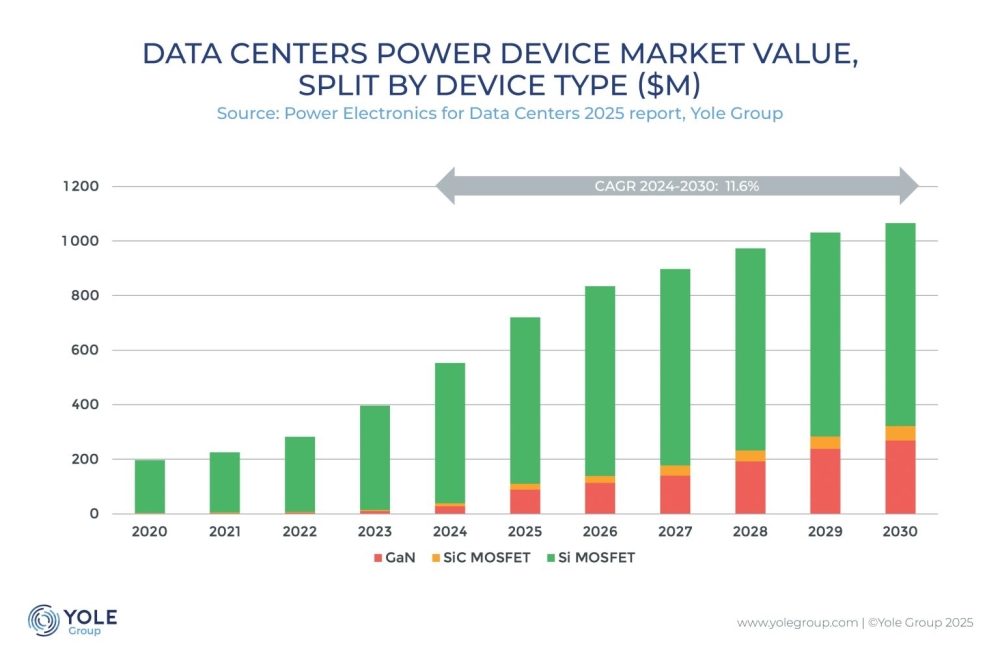

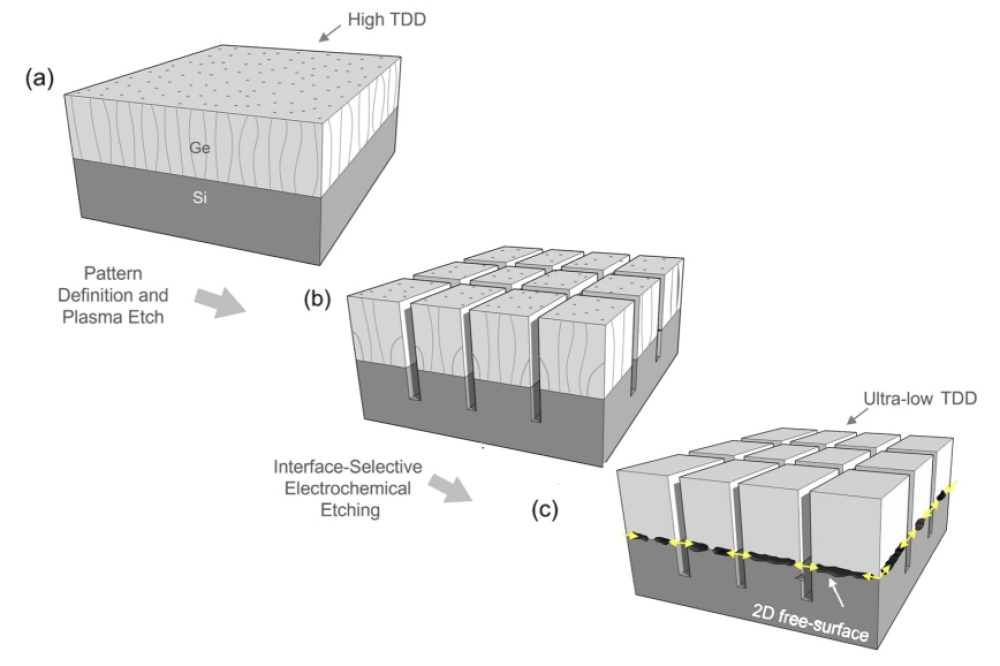

The popularity of SiC- and GaN-based power devices in electric vehicles and other high-voltage applications is on the rise. This makes it necessary to replace mechanical fuses – which have been used with conventional silicon (Si) based power converters – in order to immediately shut down the system when detecting an overcurrent, protecting the devices and avoiding costly maintenance.

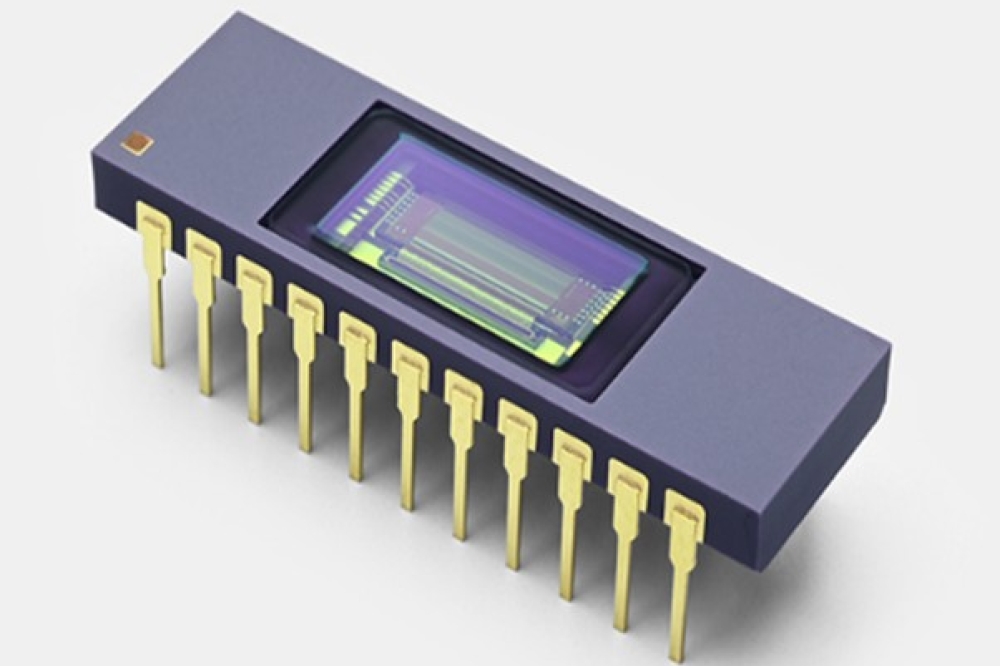

AKM is producing the CZ39 series, a coreless current sensor with a response time of 100 ns. Its fast response capability and high accuracy allow for precise detection of overcurrent and quick system shutdown. In a joint technical verification together with the Austrian research centre SAL, AKM has developed the eFuse system which solves the challenges of conventional protection systems using mechanical fuses.

This solution provides the overcurrent and short circuit protection required for next-generation high-voltage EV systems with SiC- and GaN-based power devices, such as OBCs. Furthermore, the current sensor integrated into the eFuse can efficiently regulate the current in connected subsystems, thereby reducing the overall part count.

“With this joint technology validation, we have set a new standard for eFuse technology, and we are proud to combine AKM's expertise with SAL's research capabilities to achieve this innovative result. We expect that the eFuse technology will contribute to smaller and lighter EV onboard chargers," said Toshinori Takatsuka, general manager of AKM's current sensor business.

“By utilising the latest AKM current sensing technologies, we can improve the reaction time of eFuses and the protection of wide-bandgap power converters,” said Thomas Langbauer, team lead within the Power Electronics Division at SAL.

AKM will present the results of the joint research with SAL at PCIM Europe 2024 (Nuremberg, Germany) in June. In addition, the two companies are discussing further steps as they anticipate a positive market impact.