Infineon and Stellantis partner on power architectures

Stellantis N.V. and Infineon Technologies will work jointly on the power architecture for Stellantis’ electric vehicles to support Stellantis’ ambition of offering clean, safe and affordable mobility to all.

To support this, the companies have signed major supply and capacity agreements that will serve as the foundation for the planned collaboration to develop the next generation of power architecture.

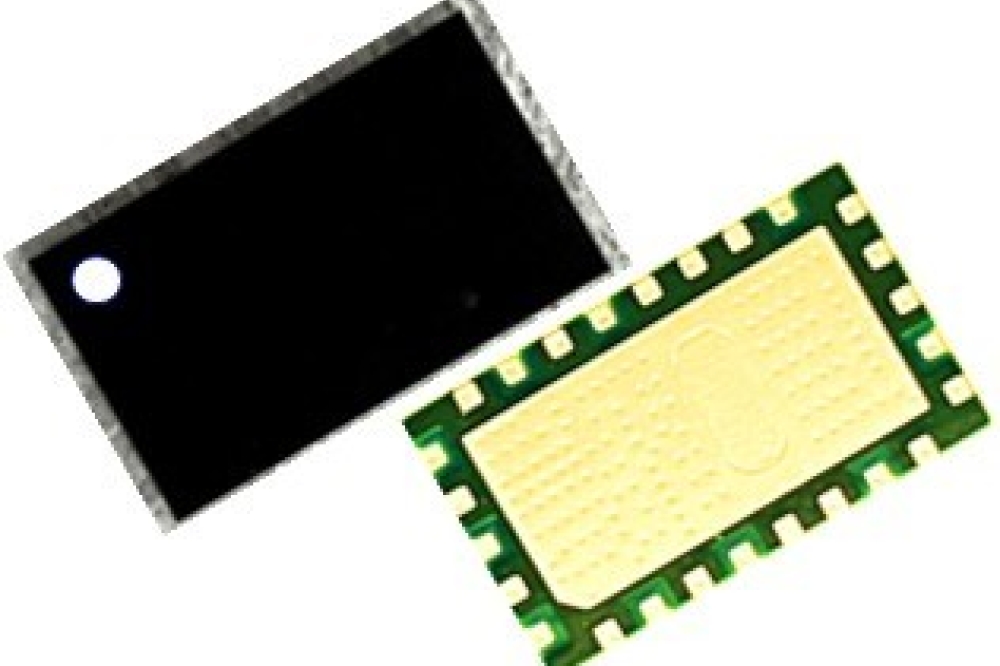

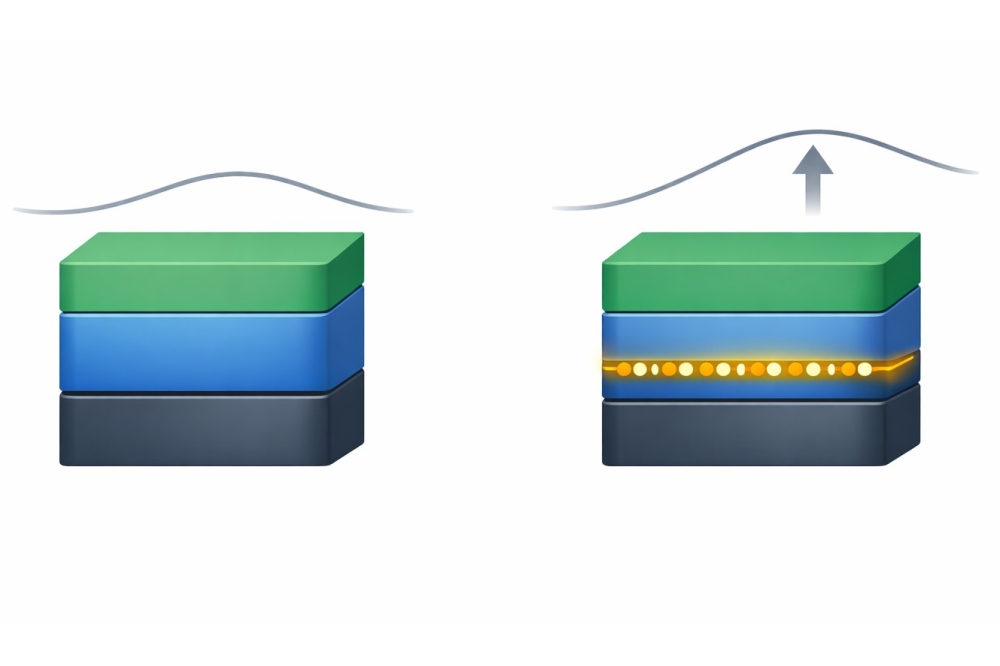

These will include Infineon’s PROFET smart power switches, which will replace traditional fuses, reduce wiring and enable Stellantis to become one of the first automakers to implement intelligent power network management. SiC semiconductors, which will support Stellantis in its efforts to standardise its power modules, improve the performance and efficiency of EVs while also reducing costs, will also be part of the deal.

To support this effort, Stellantis and Infineon are in the process of extending their cooperation with the implementation of a Joint Power Lab to define the next-generation scalable and intelligent power architecture enabling Stellantis’ software-defined vehicle.

“As outlined in our strategic plan, Dare Forward 2030, we are securing the supply of crucial semiconductor solutions required to continue our transition to an electrified future leveraging innovative E/E architectures for our next-generation platforms,” said Maxime Picat, Stellantis chief purchasing and supplier quality officer.

“Infineon is now entering a collaboration and innovation partnership with Stellantis,” said Peter Schiefer, president of Infineon’s Automotive Division. “As the world’s leading automotive semiconductor vendor, we bring our product-to-system expertise and dependable electronics to the table."