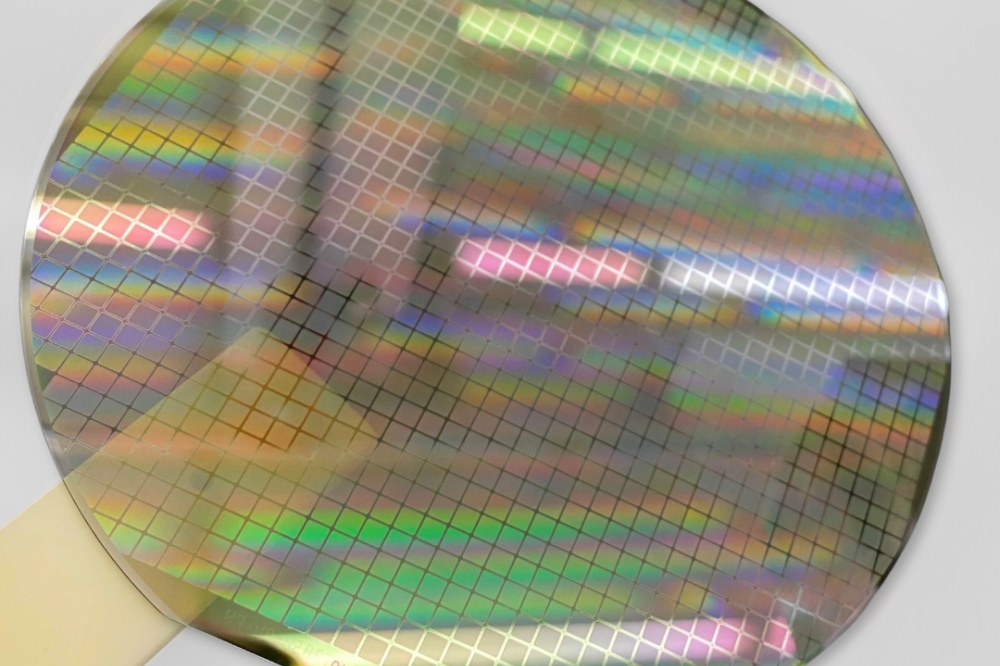

CVD Equipment addresses SiC crystal growth yield loss

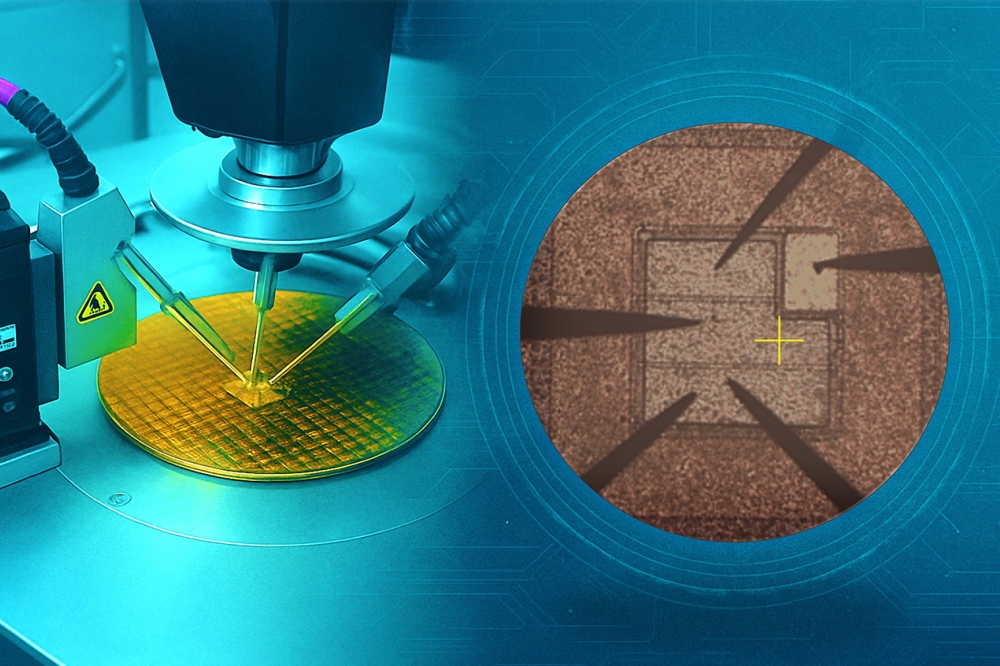

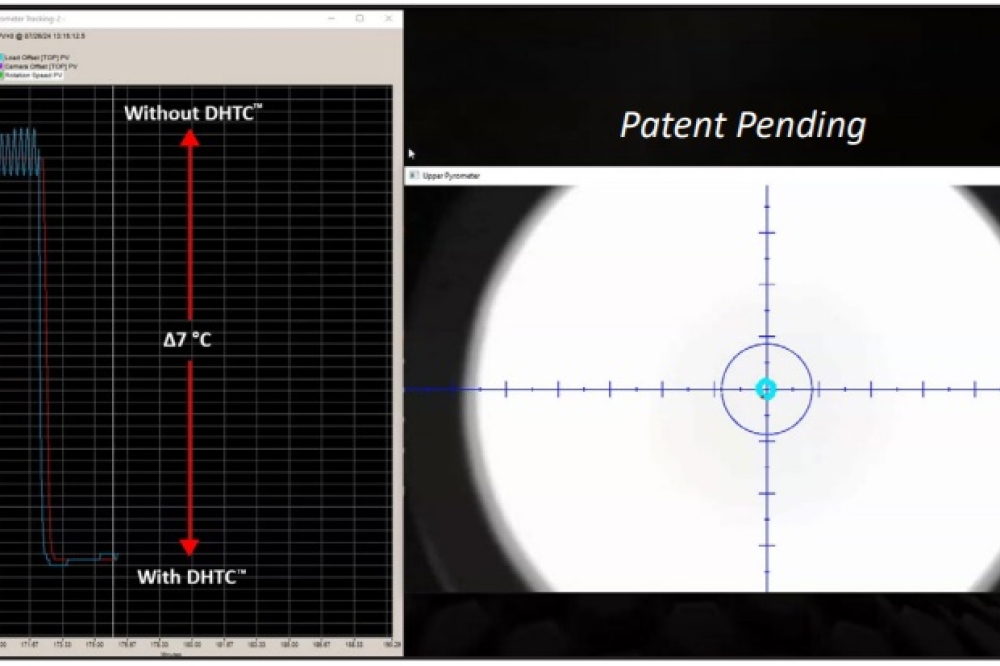

US-based CVD Equipment Corporation has introduced Dynamic Hotzone Temperature Control (DHTC ) to address SiC crystal growth yield loss attributed to temperature related dependency.

DHTC combines video processing software and mechanical hardware for tracking the centre of rotation, position of crucible viewport, and pyrometer alignment to determine, record, and compensate for misalignment of the hotzone for optimised temperature control.

Temperature variation is considered to be a main contributor to yield loss during crystal growth. There are several variables that can impact temperature measurement including misalignment from manual hotzone assembly, misalignment from manual loading, and misalignment from hotzone degradation.

This misalignment can cause variations in temperature as much as 40 °C, having an adverse impact on physical vapour transport growth repeatability within run, run-to-run, and system-to-system, and hence, crystal boule yield. Temperature measurement accuracy is a critical factor for SiC yield.

DHTC is a patent pending product solution that addresses these temperature dependent contributors to improve yield. The DHTC subsystem is engineered for temperature measurement accuracy and dynamic tracking for SiC physical vapour transport (PVT) systems.

According to the company, the solution enables highly repeatable temperature measurements and dynamically compensates for misalignment, allowing crystal growth in temperature control mode.

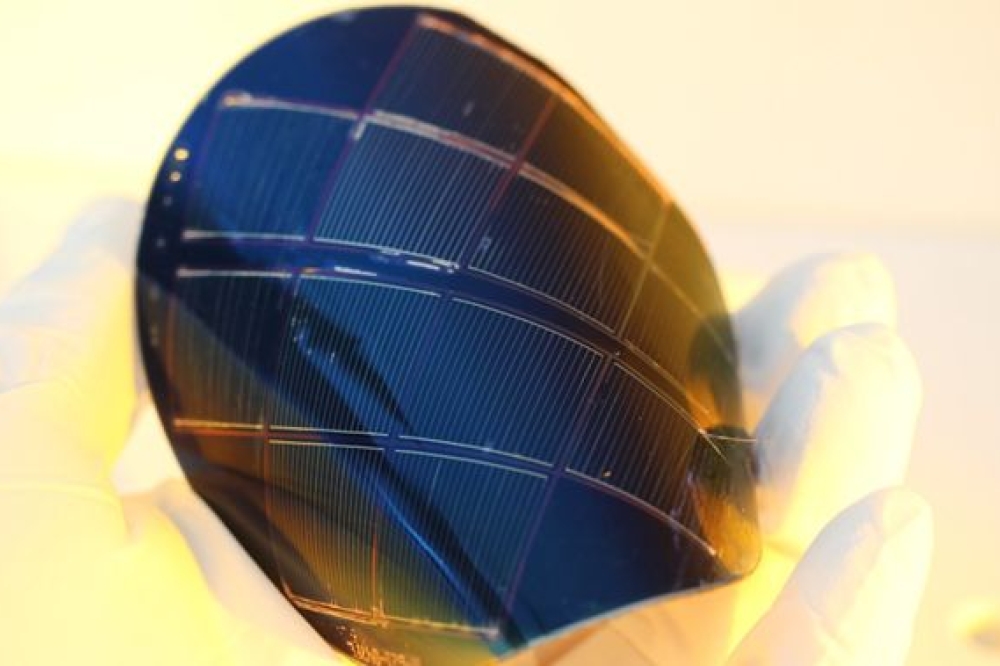

The technology is available for 150 mm and 200 mm PVT systems, and offered as an option on all of CVDE’s PVT systems. DHTC can also be offered on captive in-house manufactured PVT systems as well, for improved yield, within run, run-to-run, system-to-system repeatability and optimised temperature measurement and control.