£51m investment for Newport wafer fab

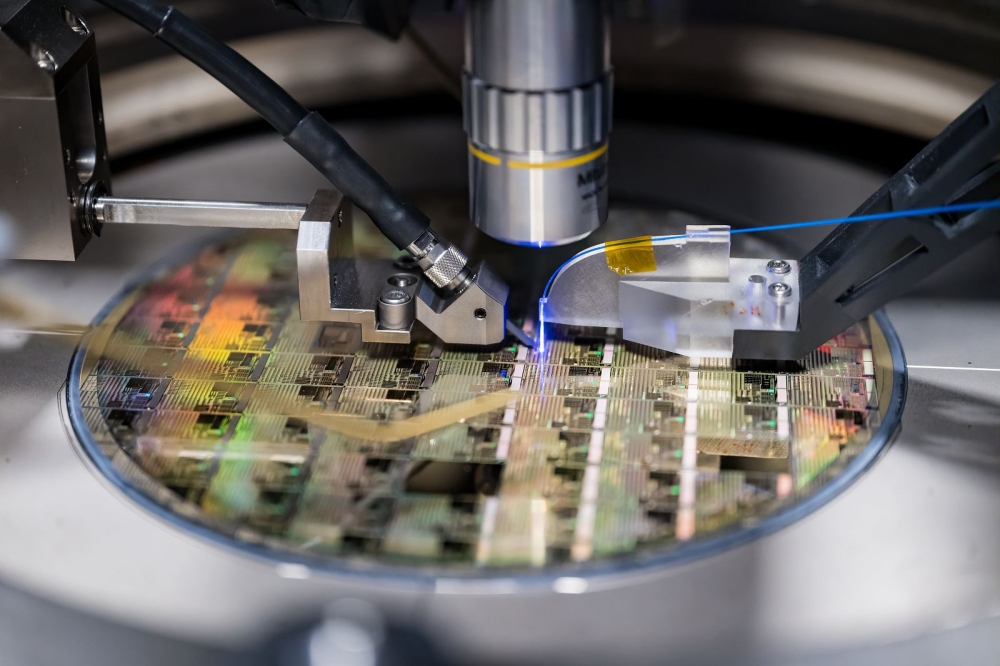

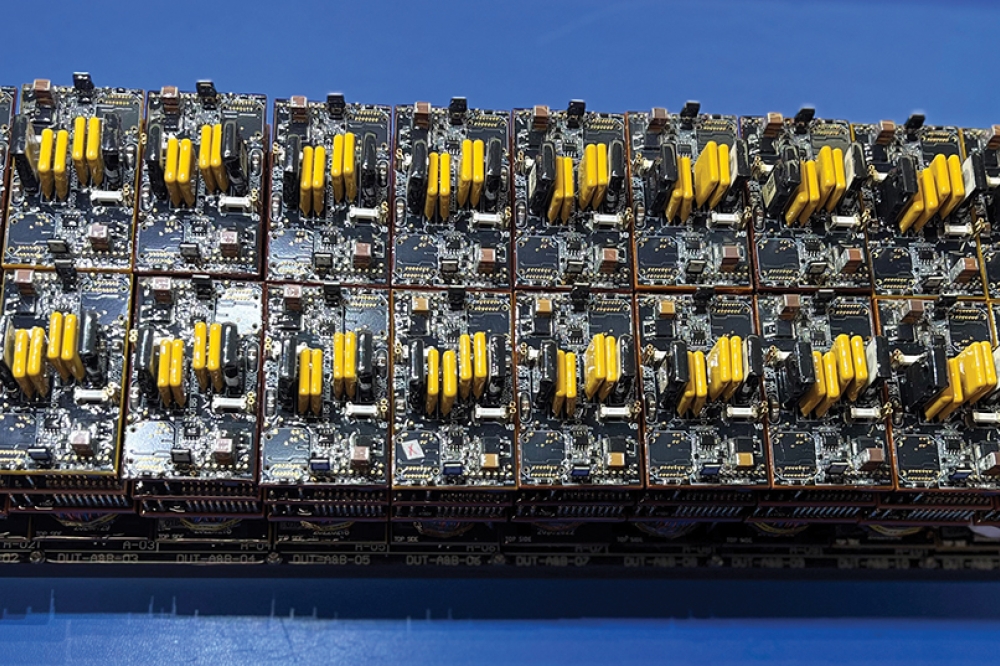

Vishay Intertechnology has announced that it is investing £51 million in Newport Wafer Fab, the UK’s largest semiconductor facility - bringing new product range capabilities and skilled job opportunities to South Wales.

The investment has been supported by £5 million of Welsh Government funding and is the latest in a list of good news for the South Wales compound semiconductor cluster – which continues to attract international interest and recognition.

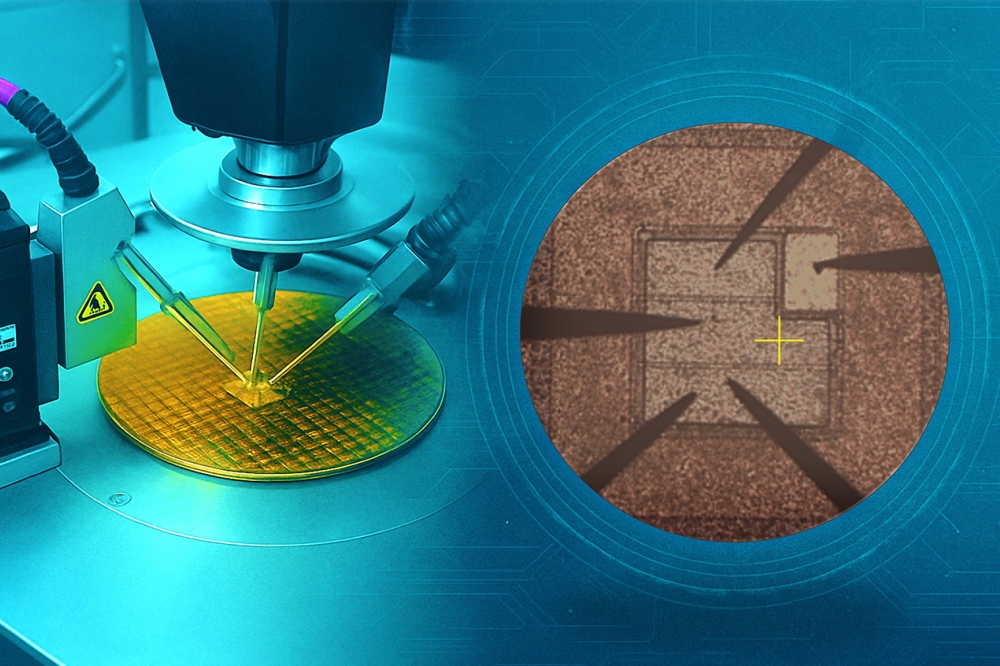

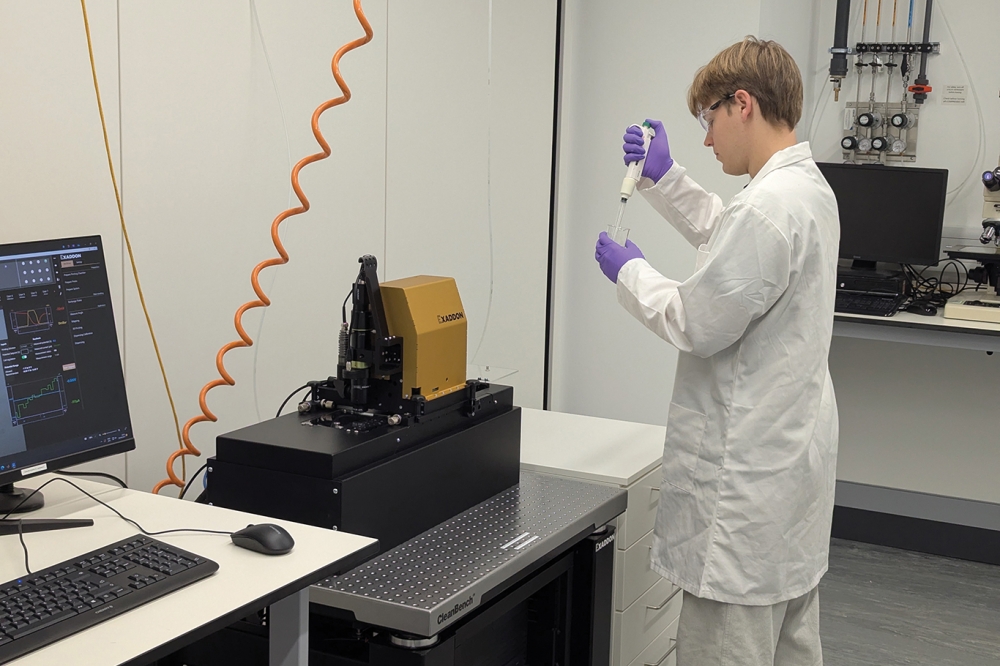

Recent progress includes: a second US owned company, KLA, constructing its new European headquarters at Imperial Park, Newport. With Welsh Government investment in the grid infrastructure at the site, the 215,000 square foot, $100 million development is creating a state-of-the-art innovation centre and manufacturing facility and will include cleanrooms for R&D and manufacturing. Recruitment of up to 750 employees is already underway.

Centre 7, a world-class facility supported by Welsh Government as part of its International Strategy, is already attracting inward investors recognising Wales as a semiconductor hotspot, with Microlink Devices, and CS Connected the first tenants at the 51,000 square foot Cardiff Gate site.

A £2.5 million Net Zero research project at Swansea University’s Centre for Semiconductor Materials. It is pioneering the reduction of building emissions for the semiconductor industry and has research agreements with industrial members such as Vishay, which counts a number of Swansea alumni amongst its executives

Cardiff University hosted ans international technical conference in October on semiconductor power devices, and Wales will welcome an inward mission by Canadian semiconductor companies in the spring.

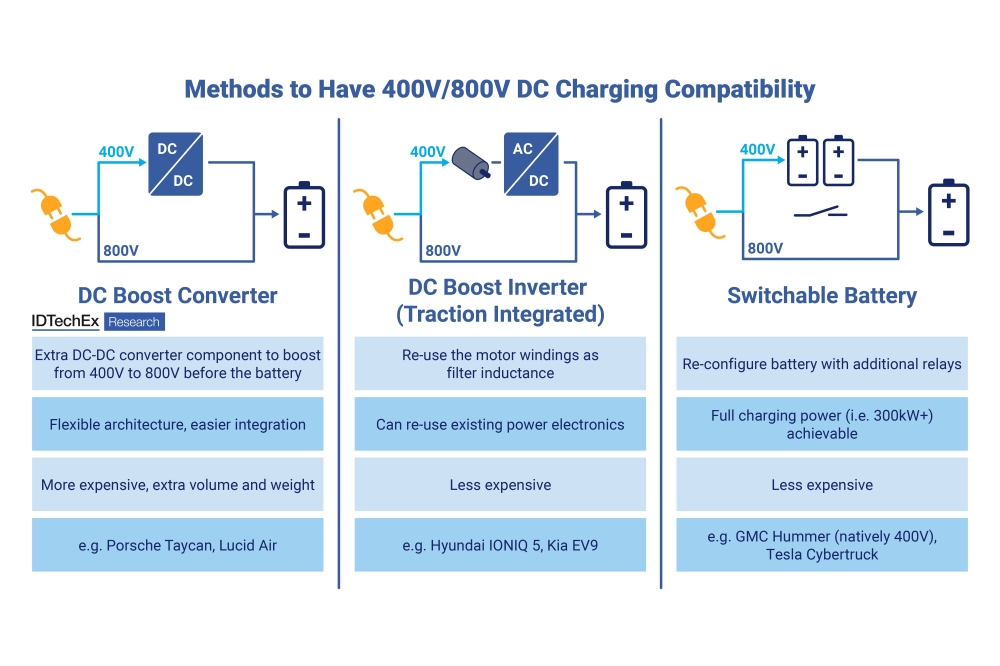

Welcoming progress, Welsh Government Economy, Energy and Planning Cabinet Secretary, Rebecca Evans said: "Compound semiconductors are all around us – in our homes and in our phones, our trains and our turbines. They are a vital, if miniature, piece of what makes the modern world tick, with extremely strong global growth projections. And we in Wales are increasingly a world-leading nation in their production and manufacture.

"Today that is more evident than ever, with our international reputation attracting significant inward investment, the provision and occupation of state-of-the-art facilities, clear links with R&D and well-paid opportunities for employment and apprenticeships.

"We are now, after a decade of seeding the cluster, reaping the rewards of our commitment which we will continue to drive forward."