Scientists design colour-changing perovskites

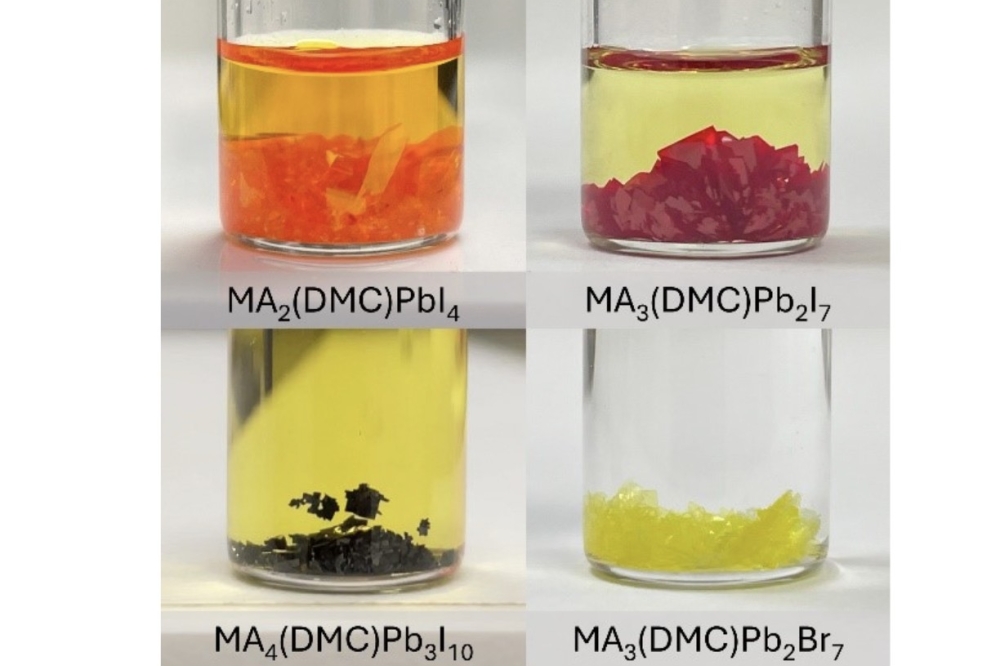

Scientists at Nanyang Technological University in Singapore, led by Nripan Mathews, have synthesised four unique 2D halide perovskites, which they've described in their paper 'Solvent-templated methylammonium-based Ruddlesden-Popper perovskites with short interlayer distances' in the Journal of the American Chemical Society,.

Ayan Zhumekenov, a research fellow at the school and lead author of the study, used a novel approach to create the new perovskites by incorporating dimethyl carbonate – a non-toxic solvent – into methylammonium-based perovskite crystals.

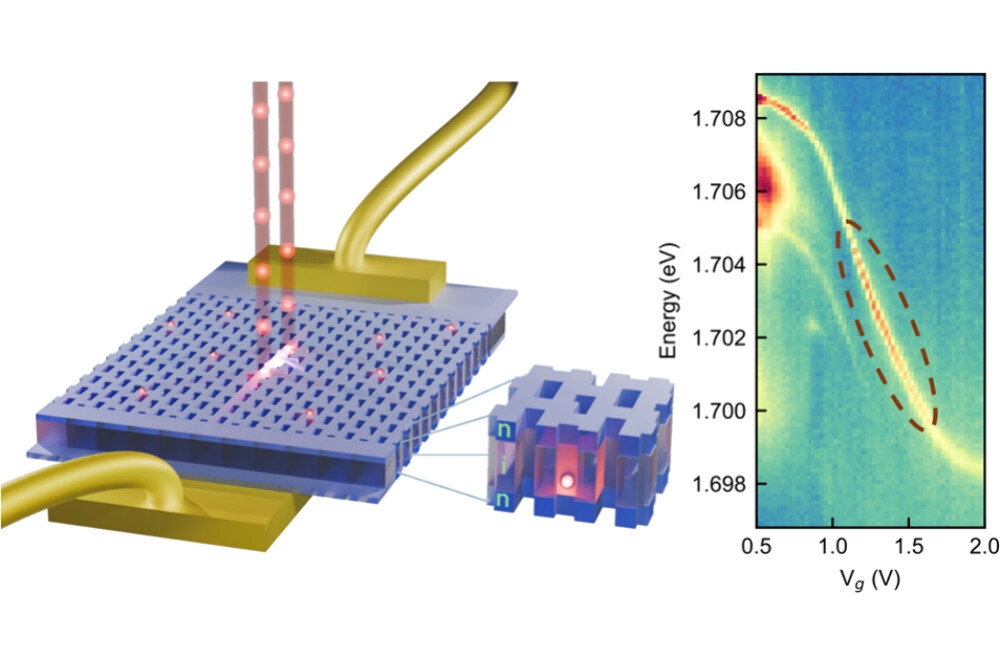

By analysing the new crystal structures, the scientists discovered that the structures’ band gap could be tuned by adjusting the ratio of methylammonium to dimethyl carbonate in them. The band gap, which determines the colour of the material, is the energy required for an electron to break free from its bound state and become conductive.

The ability to engineer the width of the band gap is important for the various applications of perovskites.

The new 2D halide perovskites also exhibit a dynamic 'switchable' behaviour. The researchers found that one of the perovskites could switch between two coloured states, changing from orange to red when heated to 80degC and reverting to its original colour when cooled to room temperature.

The scientists demonstrated that the colour-changing reaction could be repeated for 25 cycles. This phenomenon of thermochromic switching opens the door to applications such as smart coatings and heat-sensitive inks that change colour at different temperatures.

The team hopes the innovation will pave the way for technological applications of 2D halide perovskites in optoelectronics and beyond.