Cosel uses Rohm EcoSiC tech in AC-DC PSU

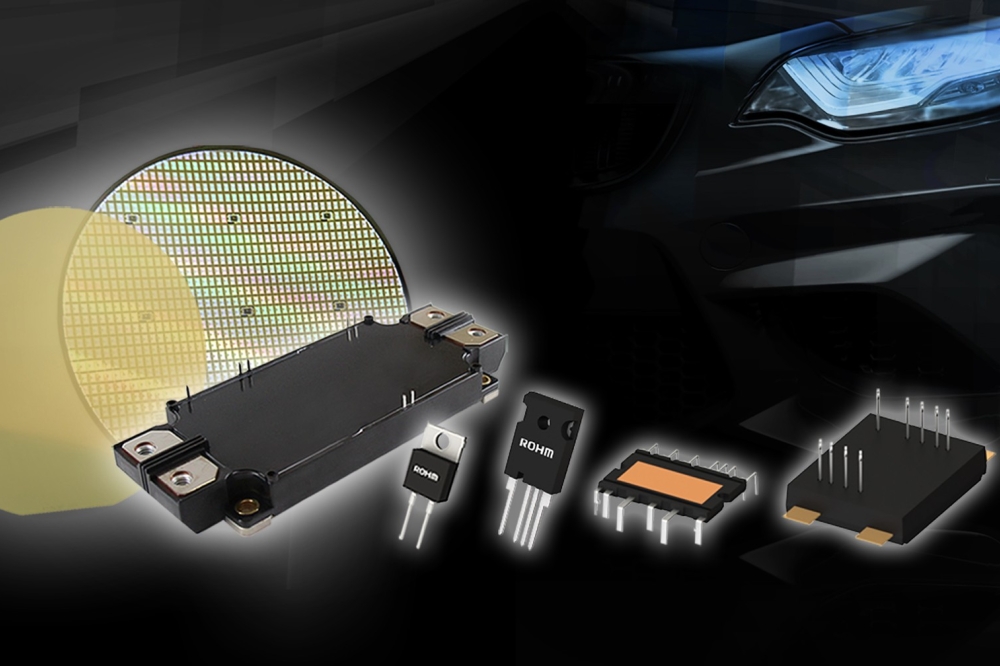

Cosel, a Japanese power supply manufacturer, is using Rohm EcoSiC products, including SiC MOSFETs and SiC Schottky barrier diodes (SBDs) in its HFA/HCA series of 3.5kW output AC-DC power supply units for 3-phase applications.

By using these devices in the forced air-cooled HFA series and conduction-cooled HCA series, Cosel has achieved up to 94 percent efficiency. The HCA series has been mass produced since 2023, while the HFA series began mass production in 2024.

Jun Uchida, a senior manager in new product development at Cosel said: “The HFA/HCA series achieve high efficiency despite delivering a high-power output of 3.5kW by incorporating Rohm's low-loss SiC power devices. Operating at high input voltages typically poses a challenge in reducing losses in high-voltage power devices, but using SiC power devices translates to significantly lower losses compared to conventional solutions, resulting in power supplies that maintains high efficiency and power density even under demanding high-power conditions.”

Rohm's Akihiro Hikasa, a general manager,, said: “We are delighted to support Cosel, an industry leader in power supply systems, by providing SiC power devices. A leading company in SiC power devices, Rohm also provides comprehensive power solutions that combine peripheral components. In addition, by addressing customer issues, we also improve device performance by incorporating the insights gained into our products. Going forward, we will continue to collaborate with Cosel to contribute to a sustainable society by enhancing the efficiency of industrial equipment that handle large amounts of power.”

The HFA/HCA series are 3.5kW power supplies featuring a wide input range (200VAC to 480VAC) that meets global power supply requirements. This allows them to be used anywhere in the world without the need to modify the power supply for each region, contributing to the standardisation of application designs.

Both forced air-cooled (HFA series) and conduction-cooled (HCA series) models - selectable based on operating environment - are available in 48V and 65V output voltage variants that can be used as power sources for a variety of high-power applications such as laser generation and MRI.