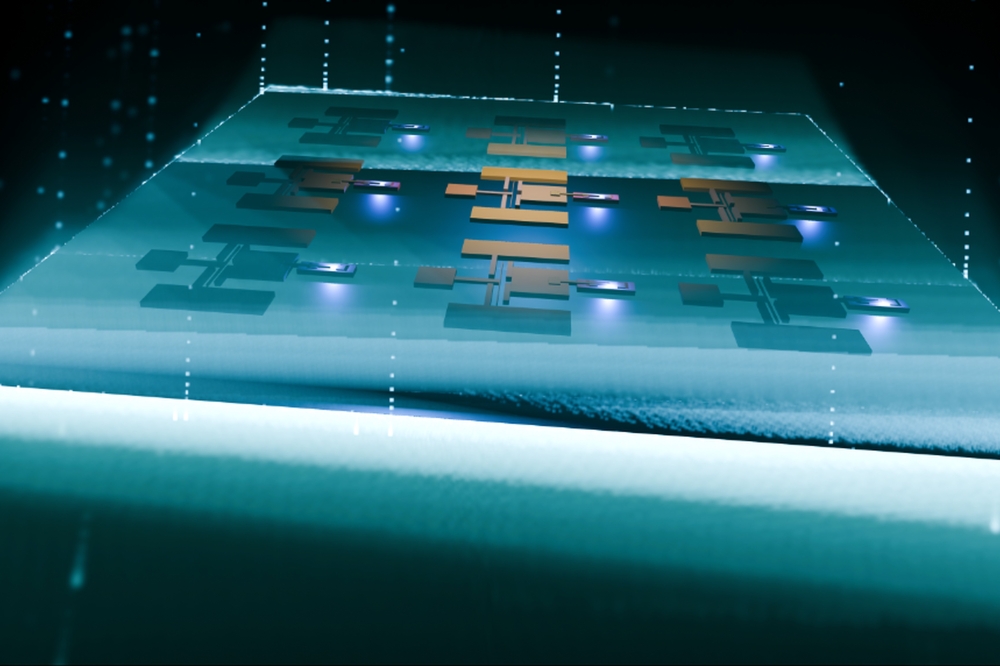

Vishay chooses Aixtron SiC tech for Newport fab

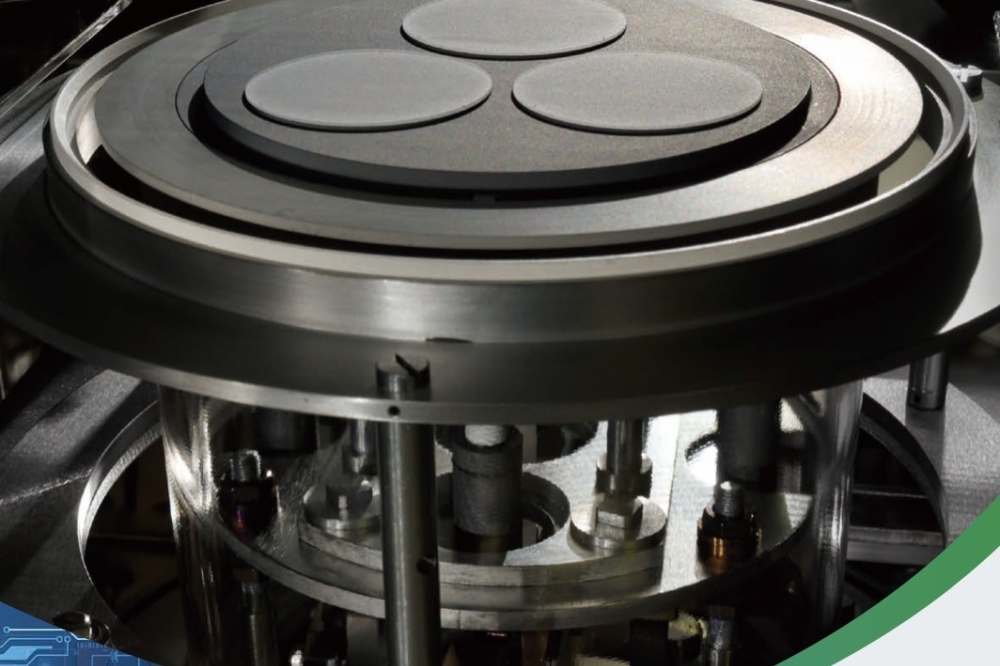

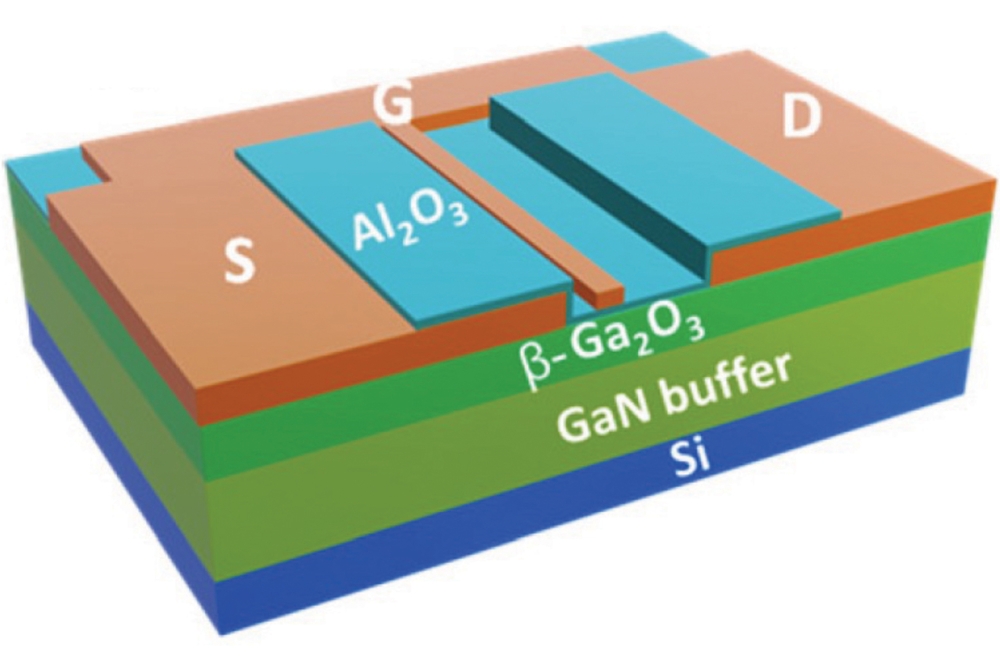

G10-SiC epitaxy production platform supports transition between 150mm and 200mm wafers

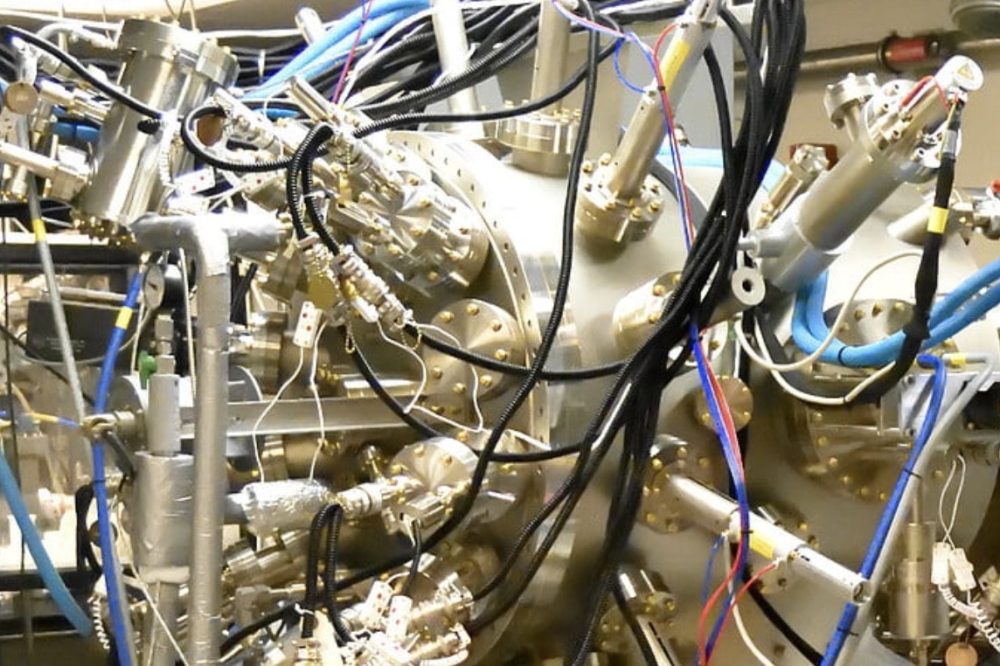

Vishay Intertechnology has chosen Aixtron’s G10-SiC epitaxy production platform for the automotive-certified Newport fab in South Wales, UK which it has recently acquired.

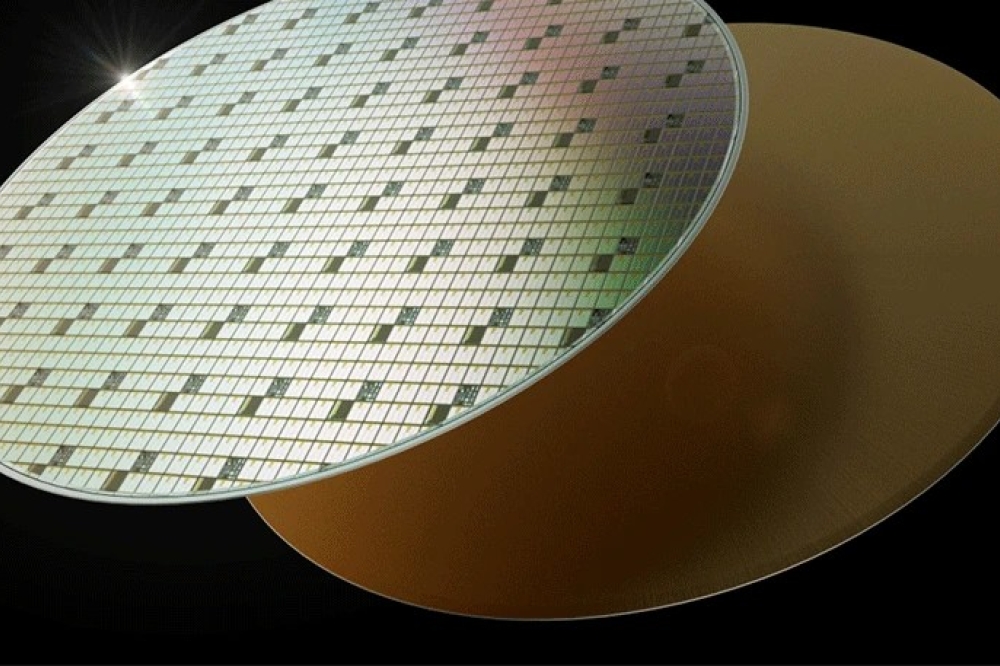

With its flexible dual wafer size configuration of 9x150 mm and 6x200 mm, the G10-SiC supports the transition between the wafer diameters.

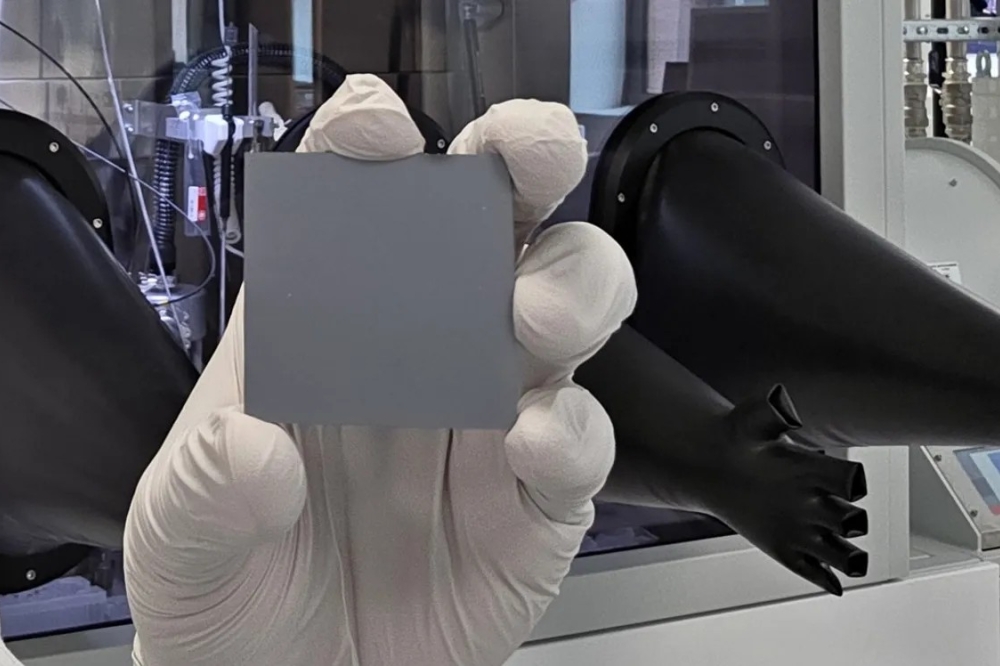

“The new G10-SiC epi production tool delivers a leading cost structure for 200 mm epitaxy, which meets Vishay’s productivity goals. This, in combination with an excellent uniformity performance on 200mm wafers, has made us choose Aixtron technology, " said Danilo Crippa, senior director R&D for SiC development, Vishay Intertechnology.

"The Aixtron team has developed a unique solution for the tightest control of doping levels and uniformity on 200 mm SiC wafers. This performance is maintained across the entire 6x200 mm wafer batch with an impressive run- to-run stability."

“We are very grateful for the opportunity to partner with Vishay and deliver our state-of-the-art epi production system with flexible 150 & 200 mm SiC wafer configuration for Vishay’s automotive-certified Newport fab in South Wales. Our strong customer service team in the South Wales Compound Semiconductor Cluster is dedicated to fully support the production ramp of Vishay’s SiC inhouse epitaxy to the highest productivity within a short period of time.”, said Frank Wischmeyer, VP SiC, Aixtron SE.