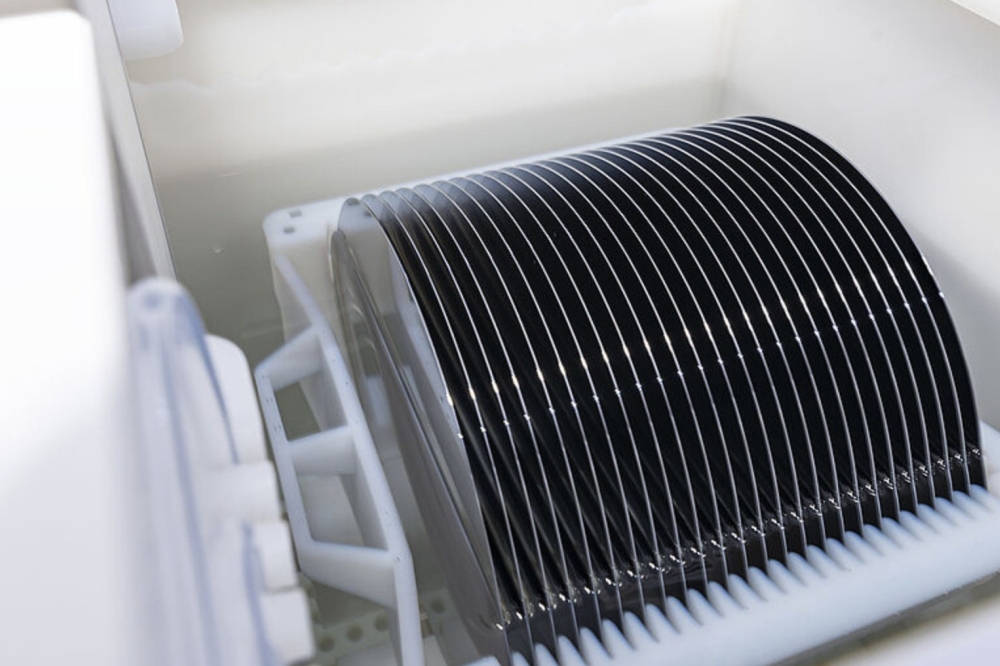

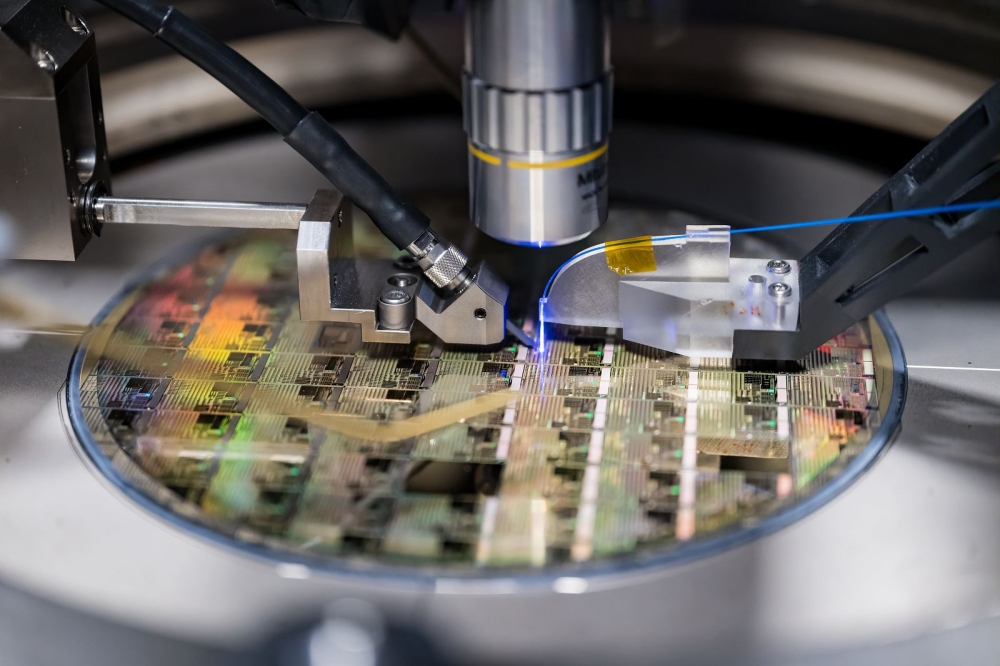

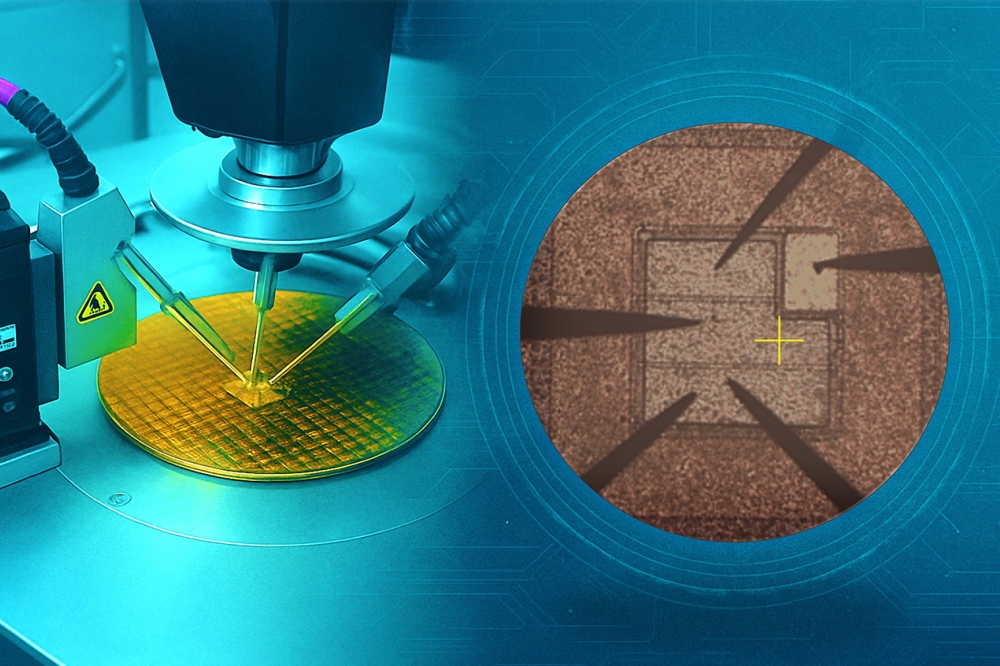

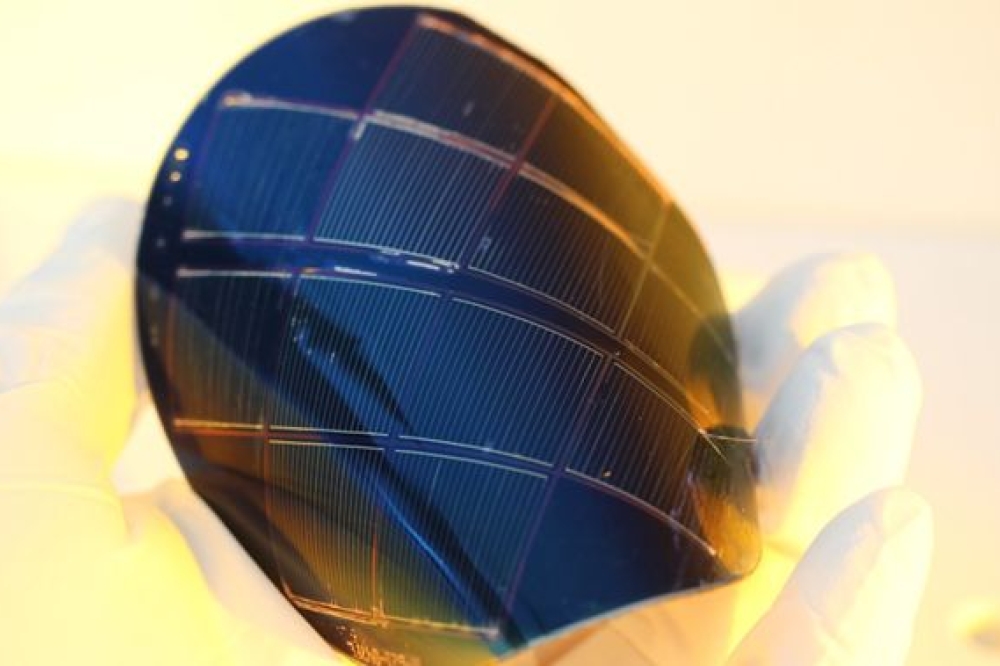

ASM launches advanced SiC epitaxy system

ASM International has introduced the PE2O8 SiC epitaxy system, a new dual chamber platform designed to address the needs of advanced SiC power devices as they transition from 6 inch to 8 inch substrates.

The PE2O8 extends ASM’s portfolio of single wafer SiC epitaxy systems (the 6 inch PE1O6 and 8 inch PE1O8 ), with a higher throughput, lower cost of ownership, dual chamber, single wafer, 6 inch and 8 inch compatible, version.

“We are at a critical inflection for SiC power products, as our customers transition from 6 inch to 8 inch wafers”, said Steven Reiter, corporate VP, and business unit head of Plasma and Epi at ASM. “Delivering a high-quality epitaxy process on larger wafers with defectivity control is critical, and we have been the industry benchmark for process uniformity with our novel chamber design. We have now extended our system capability to improve our process control and our value for customers with lower cost of ownership.”