Infineon’s expanding 2 kV portfolio

Joining Infineon’s 2kV MOSFETs are Schottky barrier diodes with identical voltage ratings.

BY RICHARD STEVENSON, EDITOR, CS MAGAZINE

High on the agenda of many design engineers in increasing the electrical efficiency of their systems. Gains on this front trim carbon dioxide emissions and utility bills, while reducing heating, which simplifies thermal management and enhances reliability.

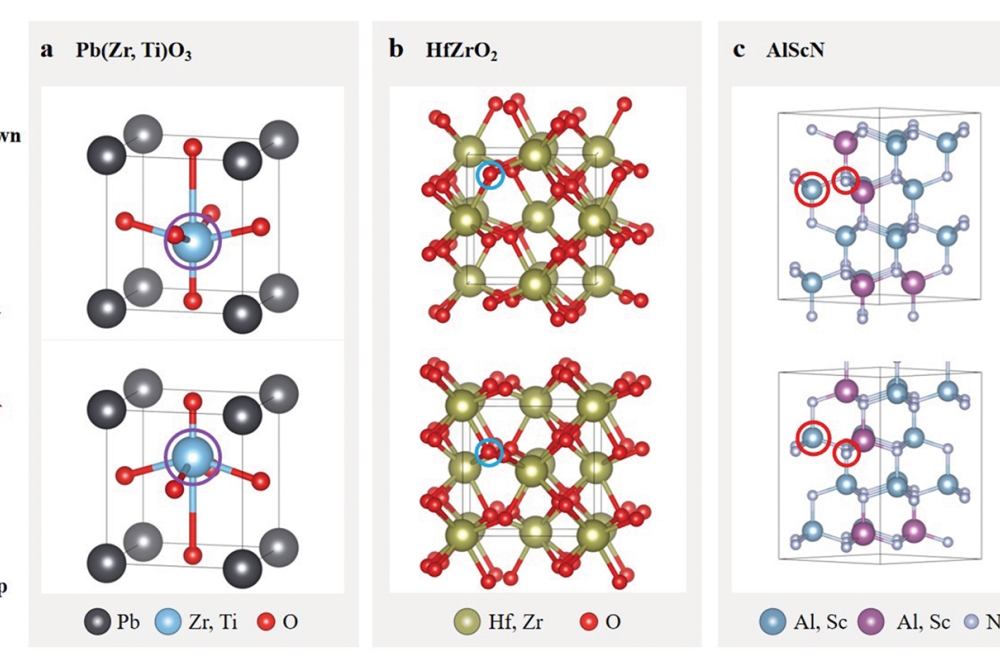

Today, two well-trodden routes may be taken to increase the efficiency of electrical systems. One of these proven pathways is to replace silicon power electronics with those that have a wider bandgap, as this reduces resistance. And the other common approach is to increase the voltage of the electrical system, and this enables a reduction in current and ohmic heating.

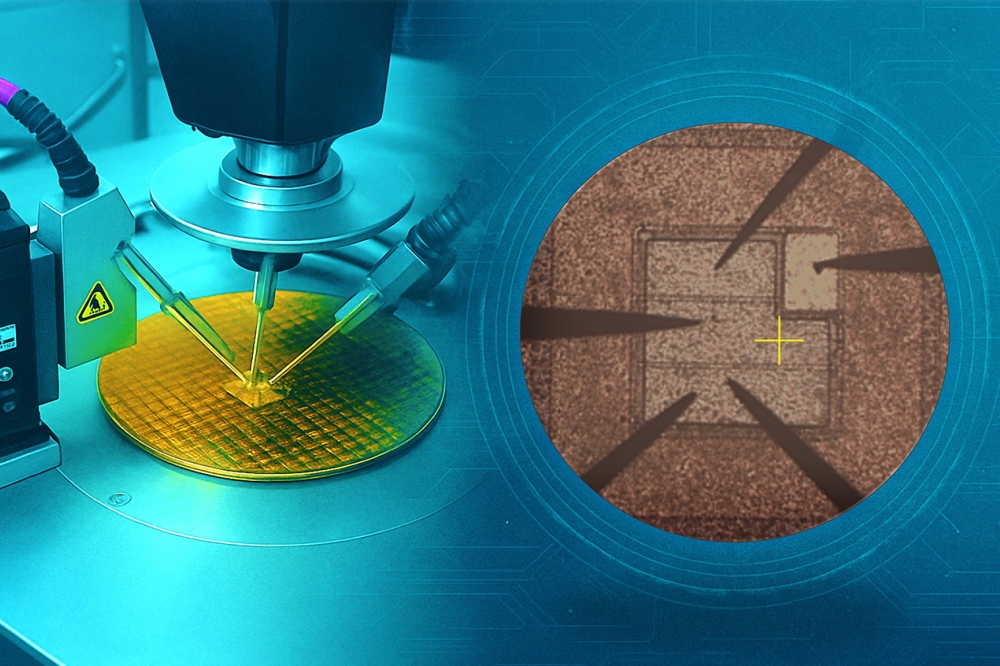

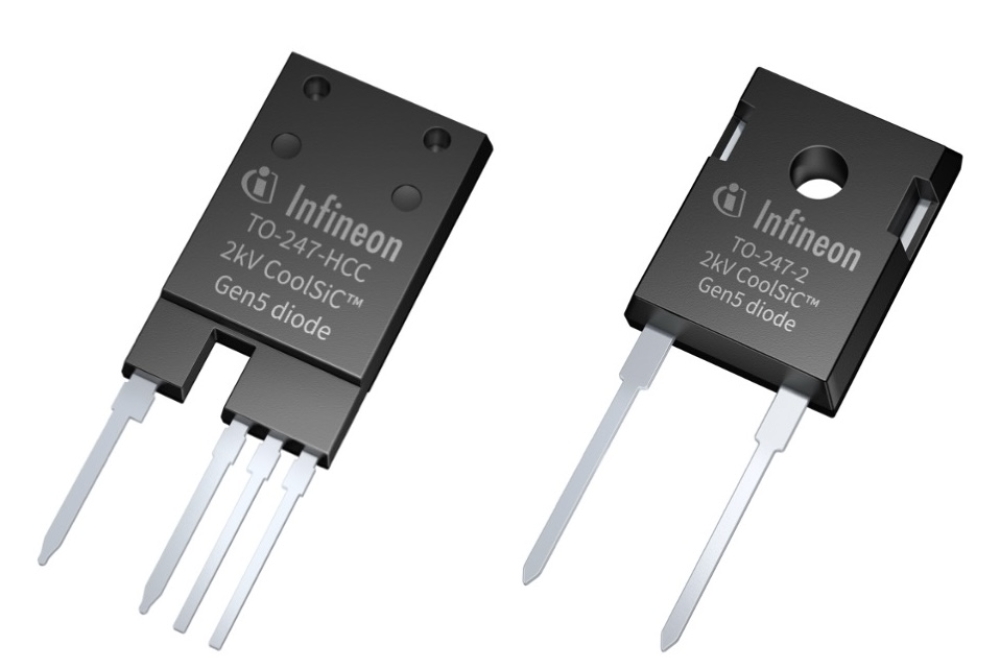

While both approaches pay dividends, rather than picking one over the other, it’s better to adopt both practices. And helping to do just that is the trailblazer of the SiC Schottky barrier diode (SBD), Infineon Technologies: it added a 2kV SiC SBD last October, and has just introduced a sibling, rated at the same voltage and housed in a different package. This pair of diodes complement Infineon’s 2 kV MOSFET, launched in March 2024.

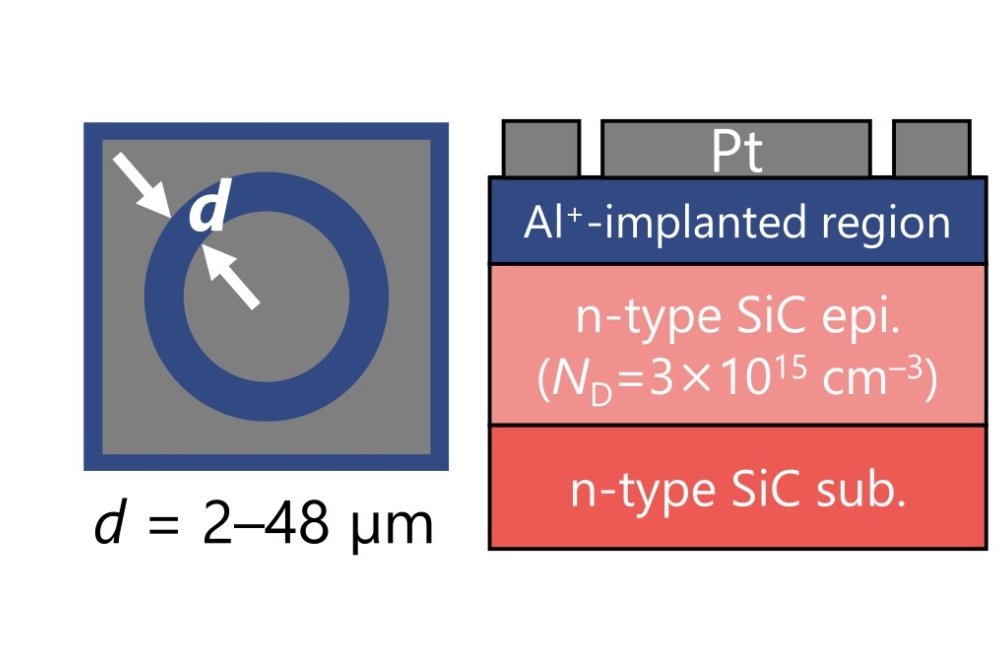

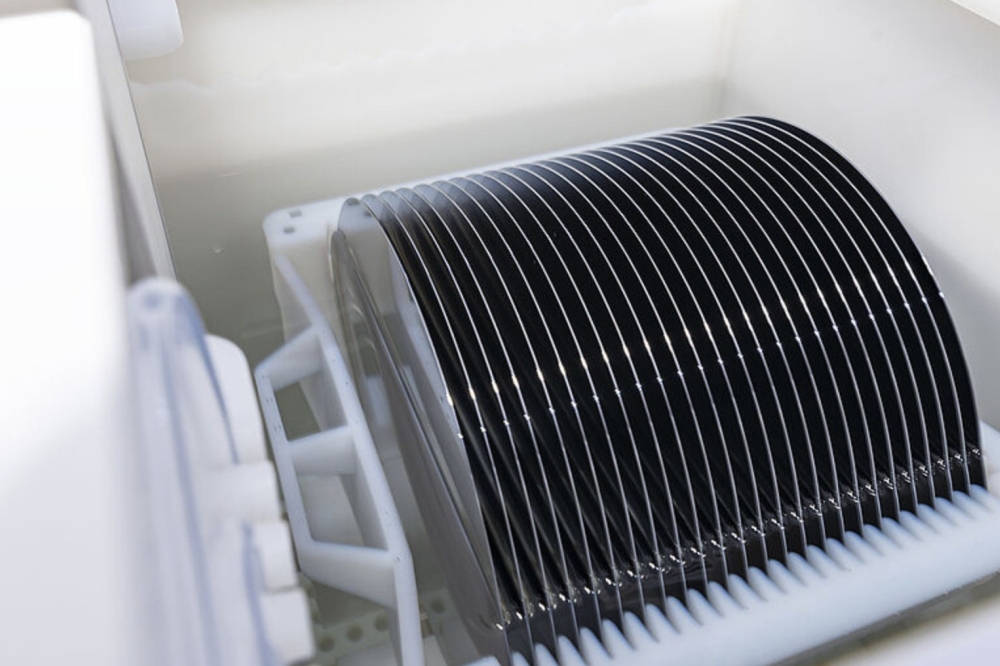

Infineon has been refining the SiC SBD for decades, having brought the first commercial device to market back in 2001. Major revisions to this diode since its debut include a new backside die metallisation and die attach technology, and more recently, the introduction of thin wafer technology, making an appearance in the fifth-generation portfolio. With these SBDs, the thickness of the die is slashed from 350 µm to just 110 µm.

In 2018, the European powerhouse introduced a sixth-generation of SiC SBDs, featuring an electrochemical barrier between the metal and semiconductor that reduces the knee voltage by around 0.1 volts.

“For 650 volts, this is a big advantage, but not so much for other blocking voltages,” remarks Peter Friedrichs, Infineon’s Vice President of SiC. “For that reason, Gen 6 remained at 650.”

By offering fifth-generation 2 kV SiC SBDs in two different packages – initially TO-247PLUS-4-HCC, and now the TO-247-2 package – Infineon is giving design engineers the opportunity to select between a diode that majors on clearance and on creepage. The former metric is related to the physical distance between the pins, with a higher value reducing the chances or arcing, while creepage considers the conductance pathway along the package surface.

“[With the TO-247PLUS-4-HCC] there’s an extra gap in the plastics that forms a longer creepage,” says Friedrichs.

It’s not clear which of the two variants will prove more popular. “We can scale both of them according to customer needs,” says Friedrichs.

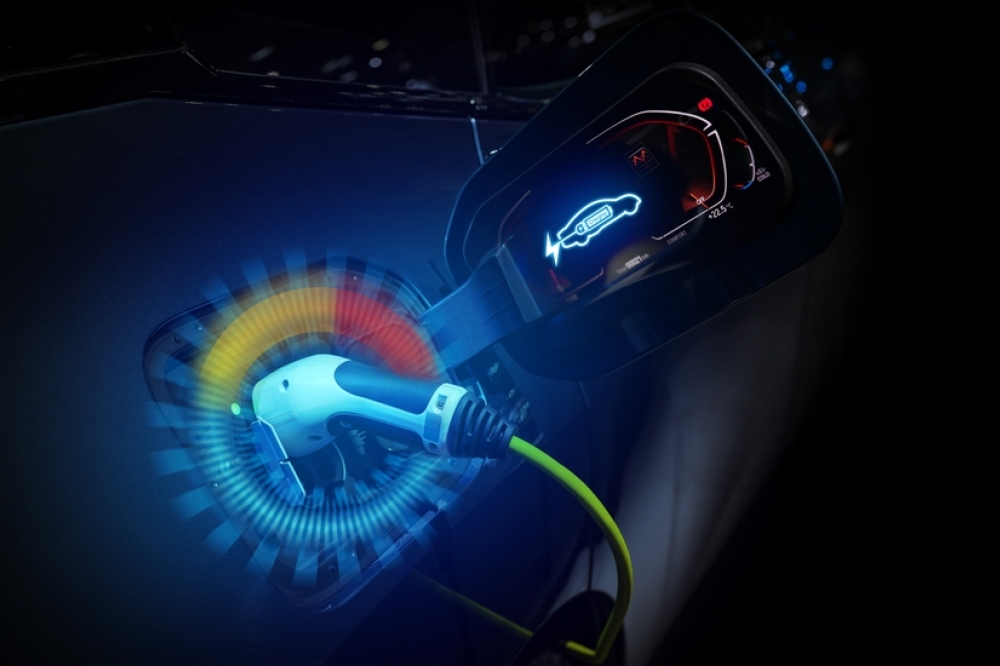

Infineon is mainly targeting the two market with its expanding portfolio of 2 kV power devices: the solar sector and the charging of electric vehicles.

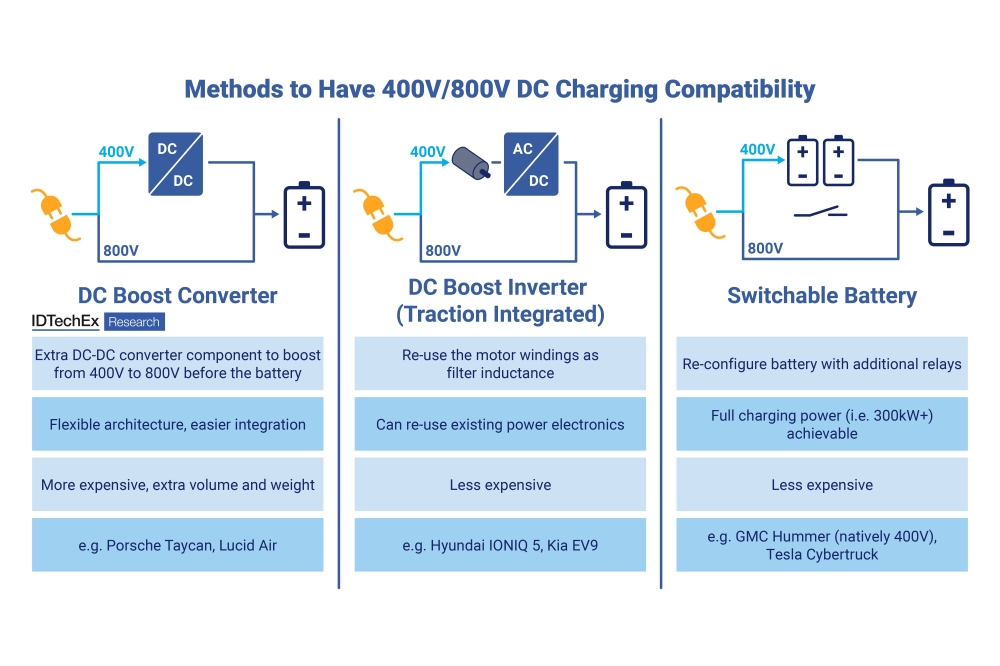

To provide high-power, fast charging of electric vehicles, bus voltages as high as 1,500 V are employed. So, to ensure reliability in this application, power devices are ideally rated at 2 kV.

Within the solar market, one of the trends has been an increase in the output voltage of the panels. “Today, 1,500-volt panels are state-of-the-art, but there are already first solutions with 2 kV and even higher,” says Friedrichs.

While it is theoretically possible to serve both these applications with silicon devices related at 2 kV, the electrical losses are unacceptable. So wide bandgap devices with a low voltage rating have been adopted, using what is referred to as a multi-level topology.

“You stack components with a lower blocking voltage in series to manage the higher voltage,” explains Friedrichs, illustrating this point by suggesting that rather than using a 2 kV device, two 1.2 kV devices may be used in series. However, as well as doubling the number of devices, multi-level topology designs increase the complexity for controlling the circuit and magnify cost at the system level.

As one would expect, Infineon’s 2 kV devices are more expensive than their 1.2 kV siblings.

“2 kV comes at a higher price, since we need a thicker epitaxial layer, a thick drift zone and a larger area. This, of course, contributes to cost, but it’s still more affordable than putting two 1.2 kV in series,” explains Friedrichs.

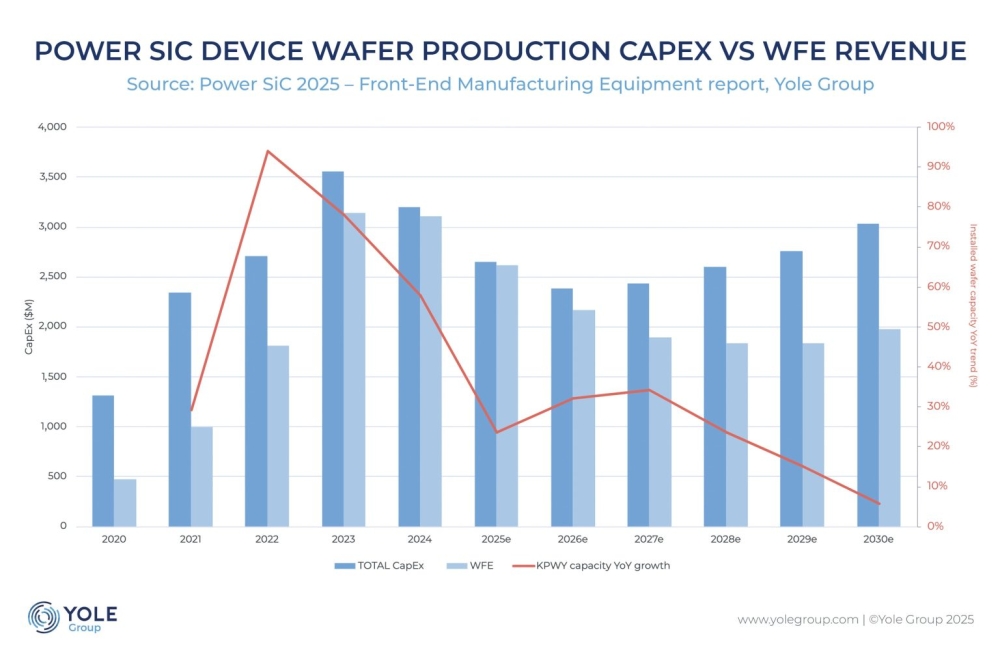

For SiC devices, the substrate accounts for a significant proportion of device cost, especially for SBDs, even though they are smaller than MOSFETs. However, substrates costs are falling, with a significant reduction in the last 12 to 15 months, according to Friedrichs.

For both of the applications that Infineon is targeting humidity is an issue, as electric vehicles and solar panels operate outdoors.

Friedrichs says that humidity is a particularly significant concern for solar applications, due to the low night-time temperatures that leads to condensation in the system. It’s not possible to address these concerns with a perfect hermetic seal, and if moisture enters the power devices, this can impact long-term reliability.

Infineon has been aware of this issue for many years, having been supplying devices to makers of solar systems since 2010. “From that point onwards, we have integrated special measures to protect the silicon carbide chips against any moisture-related degradation,” says Friedrichs.

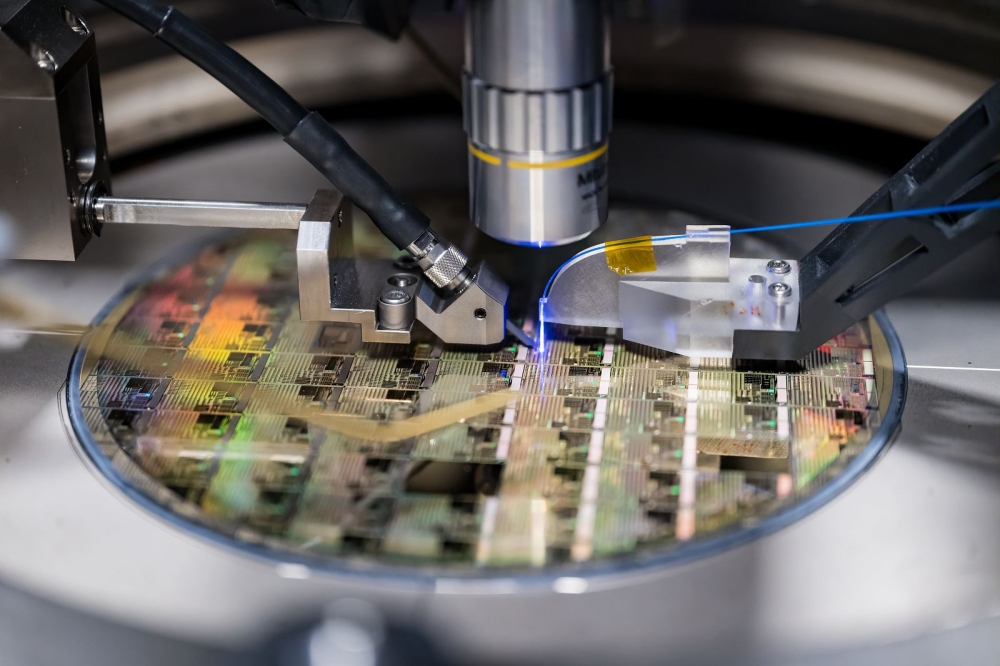

Two sites for production of its SiC portfolio have been established by Infineon: Villach, Austria; and Kulim, Malaysia.

“In Kulim, we are just starting to ramp silicon carbide front-end production,” says Friedrichs. “We start with the MOSFET. So, at the moment, all the diodes are produced in Villach.”

But with demand for SiC power devices set to rise, it will potentially not be long before the Kulim fab is serving customers all around the world with a broad and expanding portfolio that includes high-voltage SBDs.

Main Image Infineon’s fifth-generation 2 kV SiC SBDs are now available in two different packages: TO-247PLUS-4-HCC and TO-247-2 package.